Watts Celebrates 150 Years

VILT: The Latest in Watts Education

Back when COVID brought much of the industry’s traditional classroom education to a stop, Greg Gyorda was searching for another way to continue to keep training his Watts customers.

“Those were a tough two years,” says Gyorda, director of training for Watts. “Our Learning Centers were closed and our in-person Lunch and Learns weren’t happening either.”

Watts has always relied on a blended learning model giving its customers options on how they want to learn. For example, a trip to one of the company’s six Learning Centers offers top-notch formal instructor-led training with courses lasting between two to four hours. While classroom training was a part of the teaching experience, a majority of the time was spent in the center’s hands-on wet labs and also included the added benefit of chatting with other contractors. (We’ll talk more about the latest center we visited last spring, below.)

While students must travel to the centers, the Lunch and Learns travel to the students. Watts’ network of manufacturers reps head out to customer sites to conduct training events for three to 20 or more people with Watts products on display, central to the learning experience.

“I’d say pre-COVID, our Lunch and Learns were an hour,” Gyorda says. “But the world’s changed. Less is more now, so the ‘sweet spot’ is about 30 minutes.”

Gyorda added that Watts offers more than 50 approved Lunch and Learns ready to be taught on demand. Other Lunch and Learns last longer than an hour, but these are usually courses dedicated for engineers and designers that offer students Continuing Education Unit credits.

“We’ve got more than two dozen topics we can take to engineering firms,” Gyorda says, adding that Watts instructors are approved in partnership with the American Society of Plumbing Engineers and the American Institute of Architects.

Learning didn’t go completely dark during the pandemic. The Watts reps, for example, quickly adapted and began teaching the Lunch and Learn events online.

And Watts customers could always rely on a third option for education — an extensive online learning platform called Watts Works. The eLearning modules average five minutes each and require students to pass a short quiz to go onto to the next lesson.

“I’d say it’s the fastest growing part of our training program,” Gyorda adds.

The eLearning platform was actually launched in 2019 for Watts employees.

“And then after we brought online training to Watts employees, we figured this would be just as valuable to our customers,” Gyorda adds. “We took it to market to customers in the fourth quarter of 2019 and then COVID hit in 2020 and eLearning just took off.”

The online learning at Watts Works offers a great way to learn “on the go” with students using a smart phone or tablet to engage 24/7 at their own pace.

However, the modules by design are short and sweet and also a decidedly solitary pursuit for students. While effective, it’s hard to beat the chance for more in-depth courses taught live by experts and along with the camaraderie of learning with like-minded colleagues.

So to bridge that gap between the online and instructor-led experiences, Gyorda started experimenting with a fourth addition to Watts training philosophy called VILT.

Virtual Instructor Led Training

VILT, which stands for Virtual Instructor Led Training, might be a new acronym within the PHCP industry, but it’s a well-known part of many other markets’ training capacities.

VILT is interactive, online training hosted by a live virtual facilitator connecting real time through a video conferencing platform with remote participants in one or many other locations.

VILT is one of the fastest growing methods of internet-based learning delivery. Steady increases in bandwidth and collaboration software technologies have promoted VILT to be a practical and inviting solution for reaching widely dispersed learners efficiently and cost-effectively.

“VILT can be customized for the targeted audience and scheduled based on specific needs,” Gyorda explains. “Typically, we’d aim for a 30- to 45-minute session with plenty of time to ask questions throughout the program. The audience shouldn’t exceed 15 students. The capability exists for more participants, but we think a smaller, intimate approach is best to help ensure the learning experience is interactive.”

VILT typically features live demonstrations on a product or system that is captured on a live video feed. Multiple cameras can zoom in to show all the important details of the products. A PowerPoint presentation may be incorporated to reinforce certain topics.

If Watts customers haven’t heard much about VILT, that’s only because Watts has spent much of the past year on pilot programs so far. When we talked to Gyorda last summer, however, he added that the company would be rolling it “very, very soon.”

The fact that there’s an instructor — or instructors, for that matter — sets VILT apart from other typical forms on online learning.

“Online is a great way to learn, but essentially students are sitting back and listening to the instructor and following along with a presentation,” Gyorda adds. “VILT, on the other hand, offers a real dialogue between the instructor and the student for in-depth discussions.”

VILT is just the latest example of Watts’ commitment to educating the PHCP industry with various options that best match how its partners want to be trained. In addition, Watts rep Cincinnati-based Disney-McLane & Associates has been driving around its region since 2022 in a Watts Works training vehicle (For more on that read our story in PHC News: tinyurl.com/y8nmkds7.)

“We’re trying our best to reach our customers with knowledge and training,” Gyorda says. “We always say that when you buy a Watts product, we’ll train you for life. And we’re super excited to be able to reach more people whether it be VILT, our instructor-led training at the Learning Centers, Lunch & Learn program, our online options or at a stop to see the Watts Works training van.”

Fort Worth Learning Center

Watts’ commitment to training and education dates back to the early 20th century when its water-safety educational campaign informed plumbing inspectors about the critical roles both temperature and pressure regulation play in preventing water heater explosions.

The company’s current commitment to educating the trades was on full display when we attended the grand opening of Watts’ latest Learning Center in Fort Worth, Texas last April.

The center is inside a 250,000-square-foot manufacturing facility that’s homebase for PVI water heaters, but which also produces BLÜCHER stainless-steel trench and HygienicPro drains, Lync Engineered System Solutions and Ames and Watts in-building risers.

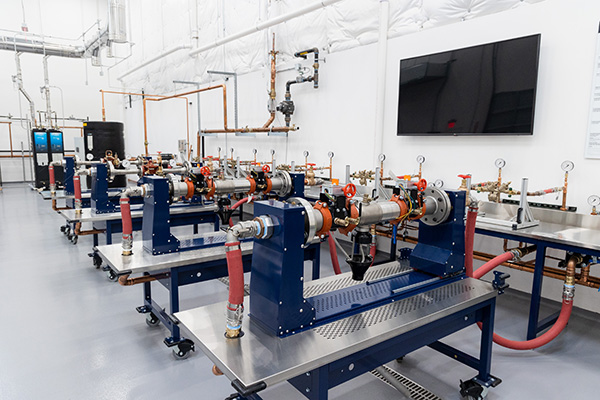

The 3,600-square foot Learning Center features an 800-square-foot classroom with space for up to 18 people, plus a 2,800-square-foot hands-on wet lab, featuring a number of Watts products, including the following:

- BLÜCHER HygenicPro Drains

- Leak Defense

- Lync Aegis W Heat Pump

- PVI Brigade; Conquest; Centurion Water Heaters

- Watts Automatic Control Valves

- Watts Big Bubba Water Filter

- Watts Cast Iron Drains

- Watts OneFlow/PVI AquaSolve Antiscale System

- Watts SentryPlus Alert Flood Protection System

- Watts/Ames In-Building Risers

- Watts/Ames/FEBCO Backflow Preventers

Products are also on display and in action in the building’s mechanical room showcase that is behind a glass wall alongside the entrance to the center.

Many of the other Learning Centers are purposefully located inside Watts manufacturing facilities so that they, too, serve as an extension of the classroom.

“There’s nothing better than bringing our customers in, training them in-person, taking a manufacturing tour and experiencing our people, our culture, and our products and solutions firsthand,” Gyorda says.

Watts opened its first Learning Center in North Andover, Massachusetts; (Watts’ corporate headquarters) in 2016; Woodland, California in 2016; St. Pauls, North Carolina in 2018; Burlington, Ontario, Canada in 2019; and finally in Fort Worth, Texas.

At the Fort Worth Learning Center, visitors can choose from a variety of courses including the following:

- Water Heaters / Boilers

- Automatic Control Valves

- Leak Detection Solutions

- Heat Pumps

- Backflow Prevention

- Water Pressure Reducing Valves

- Stainless-steel Drainage

- Cast Iron Drainage

- Water Quality Solutions

- In-building Risers

- Digital Mixing Solutions

- Smart & Connected Solutions