Watts Celebrates 150 Years

Q&A with Robert J. Pagano Jr., CEO, President and Chairperson of the Board, Watts Water Technologies Inc.

We last interviewed Robert J. Pagano Jr., CEO, president and chairperson of the board, Watts Water Technologies Inc., back in 2015. He’d just been at the helm of Watts for a year after spending a long career at ITT Corp.

When Pagano joined the company, Watts gained a seasoned executive with more than 25 years in the flow-control space and a proven track record of growing businesses through strong customer focus, new product development and strategic acquisitions.

Pagano’s first priority included a tour during which he met with the company’s leadership team, employees, customers and investors to identify needs, gaps and opportunities for the business. From there, Pagano moved quickly to develop a cohesive strategic plan that integrated a bottom-up and top-down approach focused on five key pillars: growth, operational excellence, commercial excellence, One Watts and a diverse talent and performance culture.

“It was critical from the outset to establish a clear plan and vision for the company to ensure that the entire organization was on the same page and focused on the same mission,” Pagano told us then.

He had his work cut out, not the least of which was shedding the company’s “non-core” products.

“I want Watts to be known for more than just being a producer of widgets,” he told us at the time. He ultimately eliminated around $175 million of sales related to these non-core products.

“The transformation isn’t just about selling off business though,” Pagano added. “The next part of the transformation is be known as a company that provides real solutions to its customers.”

Last August, as the company prepared to celebrate 150 years in business in 2024, we stopped by his office for an update on where he sees Watts now.

PHC News: Let’s cut right to the chase. I know one of your big goals was to ensure that Watts earns 25% of its revenue from the sale of smart and connected products by 2023. How is that going?

Pagano: The growth of smart and connected enabled products is an important part of our strategy and key to our future growth. In 2022, we ended the year with approximately 19% of total sales generated by these solutions, with 20 new products introduced. We committed more than half of our $59 million in research and development spending to expand these offerings and enhance their functionality and security. And while all our 2023 financials aren’t completed yet, I think I can say that we will achieve that goal when those numbers are finalized.

We see tremendous opportunity to enhance these efficiency and safety benefits by transforming traditional mechanical products into smart and connected solutions. Using IoT technology and cloud computing, we are giving customers new monitoring and control capabilities.

Smart and connected enabled products is just one way that we can offer solutions and not just products to our customers.

PHC News: When we interviewed you in 2015, you noted that while Watts was a great organization, it was trying too hard to be “everything to everybody.” Can you bring us up to date on where Watts is now?

Pagano: We’ve been on a journey for a while. And one of the first things we did when I got here was to develop the strategy for the company on where we’re going, what we’re doing to get there, and then I made sure I had the leadership team to implement that strategy.

When I started, I think Watts may have been too focused on the next acquisition, and as a result, lost a little focus on the customer. We’ve always been a leader, but I think we needed to put our main focus back on the customer. The customer is number one.

When I first began traveling to talk to our customers face-to-face — and believe me, I did a worldwide tour — one of the first things I learned was most of our customers didn’t know the breadth of the Watts products and brands. I’ll never forget talking to one of our major distributors, and he didn’t even know that the Powers brand was one of ours. Now certainly our wholesalers are important customers, but in the end the installer is the most important customer. But if the wholesalers who stock our products didn’t know about Powers, I doubt all of our installers knew that either.

Which is why all of our messages, whether it’s our website, signage or letterhead, now say, for example, Powers, a Watts Brand. We needed to make that connection with all our many products that they are a part of Watts.

We’re a family of brands with a huge portfolio of products that we need all our customers — wholesalers; contractors; engineers; and building and homeowners — to understand. Once they understand the breadth of the products, they’ll understand that those products offer real solutions from the time the water enters and exits a property and everything that takes place as water flows in between.

PHC News: We know from following Watts news since you arrived, that you did offload a number of product lines. Can you tell us more about what didn’t fit and at the same what does fit within your strategy?

Pagano: We began by really examining what products added value. Think of two types of products: undifferentiated and differentiated.

We used to sell hoses for washing machines. Well, that’s an undifferentiated or a commodity item. Nothing wrong with the product itself; people need them. It’s a good business but wasn’t for us. Instead of just that hose, for example, we sell a differentiated product called the IntelliFlow, which is smart enough to detect the flow of water to the washer and opens up the inlet valves. Once the washing machine completes its cycles, IntelliFlow closes the water inlet valve. Plus, it comes with a floor-mounted leak sensor if a catastrophic leak were to occur from a burst hose.

Differentiated products should form the core of Watts. We protect that core and then identify ways to expand on that core for the future.

PHC News: Now you did say that Watts, at one point in time, was a little too focused on its next acquisition. Which is not to say you are adverse to acquisitions since Watts has made many under your watch. What are you thinking about when it comes to making acquisitions?

Pagano: I’m certainly not against acquisitions. When I was at ITT, I did about a hundred of them. Again, it comes down to protecting our core; that’s the foundation of everything we do. Protect that core, be innovative and then grow. Whereas I think before we were milking the core products and using that money for the next acquisition — all while losing market share on those core products. That doesn’t make any sense. (EDITOR’S NOTE: A couple of weeks after our interview, Watts announced its acquisition of Bradley, the well-known maker of commercial washroom and emergency safety products as a strategic addition for front-of-the-wall applications.)

PHC News: What more can you tell us about the One Watts philosophy?

Pagano: The concept of One Watts was here when I arrived, but we’ve just fleshed it out. Basically, we want to align our culture, in others words, how we act, with our strategies, or, how we win, with our process, or, how we work — and with the customer always being in the center.

If you think about Watts history, it is a formation of a bunch of acquisitions that I don’t think were fully integrated. Our missions were different from brand to brand, maybe, from building to building. It didn’t feel like the One Watts culture that we have today.

So that’s what we’ve been doing — driving one consistent culture by developing a set of tools, processes and capabilities that all our 5,000 people around the world know. We have understood methods for many tasks, whether you want to enter a new market; implement lean techniques or do a turnaround. All with clear milestones, clear accountability, and you don’t move forward without the next step.

We have operating plans, business reviews, strategic plans, again, all consistent and everybody’s doing the same thing, and talking about the same things. And it’s defined by what the customer wants.

I brought some of this with me, but we’ve also taken the processes of the best of many companies, world-class companies, and we’ve made it ours.

Now we’re all talking the same language.

It can sound cliché to talk about clarifying your mission, vision, values and behaviors, but it was very important to get everybody aligned on the same page.

PHC News: So where does all this put Watts today as you prepare for 2024 and mark 150 years of the company’s history?

Pagano: Above all, we have the right team and we have the right products that offer the right solutions.

And we are making huge strides in product innovation. We used to think innovation was the next size of something. Now our smart and connected products are a great example of the kind of breakthrough innovation that can change the world. And those products will only get better as we ourselves understand them and better consider all the data that this solutions offer to our customers.

Don’t get me wrong. We have more work to do. But it’s exciting to see the progress. It’s been exciting for me to see how people have grown and how I believe we’re making this world a better place. (EDITOR’S NOTE: Others have taken notice too. Watts announced that it was recognized as a 2023 Top Place to Work in Massachusetts. The recognition is determined by a survey measuring employee opinions about their company’s direction, execution, leadership, values, pay and benefits, training and engagement.)

On a related note, our new product development is centered on three themes that the world needs: Safety and regulation; energy efficiency; and water conservation.

You can’t get through our process unless you hit one of those three. And some of them hit two of them and some hit all three. If they hit three, we call it a triple play.

Those things are so important to the world. And I think it’s just important to everybody to think about that and understand the value. When we first started our ESG [Environmental, Social and Governance] initiative, it was really focused on how we could cut carbon emissions and how do we save water.

But then, we quickly moved it to how can we help other companies on their ESG journey. And because our products save all three of those things that I just talked about, they’re really important.

PHC News: And what about that wholesaler you mentioned who didn’t know Powers was a Watts brand?

Pagano: Oh, he knows it now.

Smart and Connected Solutions Continue to Hit Their Stride

When I recently discussed with Watts experts the importance of their smart and connected products, I certainly didn’t anticipate being asked about the last time I replaced the hoses on our washing machine.

I had to admit the answer was “never” for my 8-year-old appliance. I was also surprised to hear that they’re supposed to be changed every three to five years. Washing machine hoses are constantly pressurized, and they’ll perish over time. And, as the folks at Watts reminded me, “one of those hoses will burst — and you’ll be on vacation.”

Now my washing machine hoses aren’t exactly smart and — as for being connected — that was accomplished with a pair of pliers.

Uncovering customer pain points is a big part of the product innovation conversation. There’s a lot of upfront work that must first be done to talk to customers and find out the answers to questions about where those pain points are.

Also, a smart and connected product is much more than one particular product — it’s a smart and connected solution to an entire building or home’s water resources.

Prime Example

As it turns out, Watts itself is a prime example of avoiding a pain point through the use of a smart and connected solution.

Three years ago, Watts acquired The Detection Group, a provider of wireless water security solutions and a leader in wireless water leak detection for commercial buildings. TDG’s Trident wireless water leak detection system allows for 24/7/365, real-time detection and notification of the precise location of water leaks in any size or age building.

And that system saved Watts at least $50,000 in damages on a recent, otherwise quiet Sunday morning at the company’s corporate headquarters in North Andover, Mass., after a water hose in the building’s irrigation room disconnected.

As soon as the break happened, water started flowing out — first into the irrigation room and then into a nearby shipping and receiving hallway. With no one around, it was on its way towards wreaking havoc on the carpeted space of the ground-floor offices, cubicles and meeting rooms.

The Trident system, installed a year earlier, sent out an alert to Watts facilities team members at 7 a.m. on the day of the emergency. The team responded quickly to stop the leak and then got to work cleaning up the pooled water.

Not surprisingly, water leaks are a huge pain point. Other pain points come down to pressure and temperature regulation as well as flow control.

Often times, contractors are so used to dealing with common issues that many just take them in stride and don’t think there are other ways to dealing with these issues until an emergency service call. It becomes part of life for many contractors.

Watts’ job is to peel back the onion on their objections and point out that there might be a better way. And Watts thinks they’re at the point where they can provide contractors with that better way that really targets the primary pain points a contractor may have when it comes to common plumbing and heating products.

Products

In the 150 years since its founding, Watts has learned the importance of investing in emerging technology. The company’s recent investment in connected products and solutions now serve many markets worldwide.

As noted in our interview with CEO Robert J. Pagano Jr., the company anticipated that it would achieve the goal in 2023 to achieve 25% of its revenue from the sale of smart and connected products.

According to its 2022 Sustainability Report, 52% of Watts products fall under the category of “residential and commercial flow,” with “many of our flow-control and protection products now smart and connected enabled products, warning of leaks and floods with alerts to building management systems and/or personal devices, giving our customers greater insight into their water management and the ability to shut off the water supply to avoid waste and mitigate damages.”

In addition, Watts categorizes another 31% of its products as “HVAC and gas products,” with the majority of these featuring “advanced controls enabling customers to easily connect to the building management system for better monitoring, control, and operation.

Let’s look at just some of Watts’ smart and connected products portfolio:

SentryPlus Alert is a connected and IoT-enabled reduced pressure zone (RPZ) backflow preventer and flood protection shutdown automatic control valve designed to provide facility managers with 24/7/365 peace-of-mind protection against flooding because of catastrophic RPZ backflow discharge.

The advanced protection provided by an RPZ backflow preventer comes with the possibility of discharge through the relief valve should the valve become compromised. While this is part of the backflow preventer doing its job, it’s an excessive discharge that can cause flood damage to a facility. SentryPlus Alert detects potential flood conditions, can shut down the water supply, and issue multi-channel alerts so action can be taken — all before major damage occurs. Once installed, the system stands on guard from detection to protection, allowing service managers or building owners to be there, even when they’re not.

Watts RPZs are shipped standard with a flood sensor at no charge. The installer needs only to add a cellular or BMS monitoring kit to activate it. Watts also offers a monitoring kit with sensor for existing RPs.

In addition, Watts offers a Cellular Gateway Sensor Connection Kit. Rather than hard-wiring into a BMS (Building Management System) control panel, Watts’ cellular gateway sensor can connect to a local cell signal to transmit an alarm for a water discharge event.

Using the Watts SentryPlus application powered by Syncta, a user can build a profile, register and activate their backflow valve, then be able to monitor one or multiple valves in a dashboard. The kit comes with a two-year subscription service, then changes to a month-to-month subscription fee.

A recent enhancement is Watts’ new Tamper Switch. It’s an important part of their smart and connected backflow story and a key solution for backflow assemblies that are used to supply water to a fire protection sprinkler system. Many backflow assemblies on fire sprinkler lines are chained or have an alarm added to them after installation to prevent tampering; our integrated tamper switch comes preinstalled and is designed to immediately send a signal to the fire panel if someone tries to turn the yoke on the OS&Y gate valves. Users need only to wire the switch to the panel.

Over a decade ago, Watts acquired North America’s leading provider of sophisticated electronic controls for the radiant heat and snowmelt industry — tekmar — a move that has since positioned Watts as market leader of ever-more sophisticated, connected thermostats and system controls.

Controlling and managing comfort — and, with snowmelt, safety too — is ever more important. The technology now allows real-time access to information, data collection and management of all facets of the comfort/control/safety equation — whether through a sophisticated BAS (BACnet), or on a smaller residential scale.

A recent advancement has been the development of sophisticated controls that can be installed using traditional two-wire connections commonly found in installation, making it possible to provide advanced control for systems in older homes or buildings — without the need and expense to run new wiring between thermostats and the mechanical room.

Watts also owns AERCO International, a leading manufacturer of high-efficiency commercial boilers and water heaters.

AERCO’s onAER offers advanced predictive maintenance through AERCO’s affordable, easy-to-use, remote system health monitoring with instant access to unit performance details, event history, maintenance schedules and more. The technology ensures that systems operate at peak performance while reducing cost of ownership. The cloud-based software helps building/facility owners avoid lost revenue due to undetected equipment faults and downtime.

Element Q from Lync is a packaged domestic water solution — offering digital mixing for domestic hot water (DHW), on-board filtration and UV for pre-treatment.

Element Q brings the functionality of a full DHW system in addition to multi-barrier, waterborne pathogen protection and remote monitoring, into one compact, smart appliance as a single-sourced solution.

Dormont released the FloPro-MD 3-in-1 gas flow and pressure measurement system as a means of temporarily monitoring gas flows to help service technicians and installers more easily perform equipment start-ups, commissioning, and gas flow issue troubleshooting. It offers 24/7/365 monitoring of fuel pressure at many points within a gas-piped network, overpressure protection alarm and shutdown capabilities.

Lastly, there’s the release of the IoT enabled Powers IntelliStation Jr. — the “little brother” to the Powers IntelliStation digital mixing station for large commercial domestic water systems, typically found in hospitals and hotels, and as part of a building management system.

Originally released in 2017 with BACnet capabilities, an enhanced cloud-connected version was launched in 2021 with mobile and web applications; data analytics, device witnessing, management and reporting.

The technology offers programmable set point range of 60 F to 180 F, water temperature control +/- 2 F in accordance with ASSE 1017, user-selected high and low temperature alerts and a scheduling feature with temperature setback. Its high temperature sanitization mode addresses waterborne bacteria. IntelliStation Jr. is also self-balancing, which prevents overnight temperature creep by balancing the hot water distribution system during low- to no-demand periods.

With IoT capabilities, “Jr.” offers digital mixing with remote control and monitoring of tempered water distribution. Users achieve safety at-a-glance with remote visibility on the accompanying mobile and web app. Configurable on-site and easy to install, IntelliStation Jr. doesn’t require factory pre-programming, a laptop, or special software when commissioning or adjusting.

VILT: The Latest in Watts Education

Back when COVID brought much of the industry’s traditional classroom education to a stop, Greg Gyorda was searching for another way to continue to keep training his Watts customers.

“Those were a tough two years,” says Gyorda, director of training for Watts. “Our Learning Centers were closed and our in-person Lunch and Learns weren’t happening either.”

Watts has always relied on a blended learning model giving its customers options on how they want to learn. For example, a trip to one of the company’s six Learning Centers offers top-notch formal instructor-led training with courses lasting between two to four hours. While classroom training was a part of the teaching experience, a majority of the time was spent in the center’s hands-on wet labs and also included the added benefit of chatting with other contractors. (We’ll talk more about the latest center we visited last spring, below.)

While students must travel to the centers, the Lunch and Learns travel to the students. Watts’ network of manufacturers reps head out to customer sites to conduct training events for three to 20 or more people with Watts products on display, central to the learning experience.

“I’d say pre-COVID, our Lunch and Learns were an hour,” Gyorda says. “But the world’s changed. Less is more now, so the ‘sweet spot’ is about 30 minutes.”

Gyorda added that Watts offers more than 50 approved Lunch and Learns ready to be taught on demand. Other Lunch and Learns last longer than an hour, but these are usually courses dedicated for engineers and designers that offer students Continuing Education Unit credits.

“We’ve got more than two dozen topics we can take to engineering firms,” Gyorda says, adding that Watts instructors are approved in partnership with the American Society of Plumbing Engineers and the American Institute of Architects.

Learning didn’t go completely dark during the pandemic. The Watts reps, for example, quickly adapted and began teaching the Lunch and Learn events online.

And Watts customers could always rely on a third option for education — an extensive online learning platform called Watts Works. The eLearning modules average five minutes each and require students to pass a short quiz to go onto to the next lesson.

“I’d say it’s the fastest growing part of our training program,” Gyorda adds.

The eLearning platform was actually launched in 2019 for Watts employees.

“And then after we brought online training to Watts employees, we figured this would be just as valuable to our customers,” Gyorda adds. “We took it to market to customers in the fourth quarter of 2019 and then COVID hit in 2020 and eLearning just took off.”

The online learning at Watts Works offers a great way to learn “on the go” with students using a smart phone or tablet to engage 24/7 at their own pace.

However, the modules by design are short and sweet and also a decidedly solitary pursuit for students. While effective, it’s hard to beat the chance for more in-depth courses taught live by experts and along with the camaraderie of learning with like-minded colleagues.

So to bridge that gap between the online and instructor-led experiences, Gyorda started experimenting with a fourth addition to Watts training philosophy called VILT.

Virtual Instructor Led Training

VILT, which stands for Virtual Instructor Led Training, might be a new acronym within the PHCP industry, but it’s a well-known part of many other markets’ training capacities.

VILT is interactive, online training hosted by a live virtual facilitator connecting real time through a video conferencing platform with remote participants in one or many other locations.

VILT is one of the fastest growing methods of internet-based learning delivery. Steady increases in bandwidth and collaboration software technologies have promoted VILT to be a practical and inviting solution for reaching widely dispersed learners efficiently and cost-effectively.

“VILT can be customized for the targeted audience and scheduled based on specific needs,” Gyorda explains. “Typically, we’d aim for a 30- to 45-minute session with plenty of time to ask questions throughout the program. The audience shouldn’t exceed 15 students. The capability exists for more participants, but we think a smaller, intimate approach is best to help ensure the learning experience is interactive.”

VILT typically features live demonstrations on a product or system that is captured on a live video feed. Multiple cameras can zoom in to show all the important details of the products. A PowerPoint presentation may be incorporated to reinforce certain topics.

If Watts customers haven’t heard much about VILT, that’s only because Watts has spent much of the past year on pilot programs so far. When we talked to Gyorda last summer, however, he added that the company would be rolling it “very, very soon.”

The fact that there’s an instructor — or instructors, for that matter — sets VILT apart from other typical forms on online learning.

“Online is a great way to learn, but essentially students are sitting back and listening to the instructor and following along with a presentation,” Gyorda adds. “VILT, on the other hand, offers a real dialogue between the instructor and the student for in-depth discussions.”

VILT is just the latest example of Watts’ commitment to educating the PHCP industry with various options that best match how its partners want to be trained. In addition, Watts rep Cincinnati-based Disney-McLane & Associates has been driving around its region since 2022 in a Watts Works training vehicle (For more on that read our story in PHC News: tinyurl.com/y8nmkds7.)

“We’re trying our best to reach our customers with knowledge and training,” Gyorda says. “We always say that when you buy a Watts product, we’ll train you for life. And we’re super excited to be able to reach more people whether it be VILT, our instructor-led training at the Learning Centers, Lunch & Learn program, our online options or at a stop to see the Watts Works training van.”

Fort Worth Learning Center

Watts’ commitment to training and education dates back to the early 20th century when its water-safety educational campaign informed plumbing inspectors about the critical roles both temperature and pressure regulation play in preventing water heater explosions.

The company’s current commitment to educating the trades was on full display when we attended the grand opening of Watts’ latest Learning Center in Fort Worth, Texas last April.

The center is inside a 250,000-square-foot manufacturing facility that’s homebase for PVI water heaters, but which also produces BLÜCHER stainless-steel trench and HygienicPro drains, Lync Engineered System Solutions and Ames and Watts in-building risers.

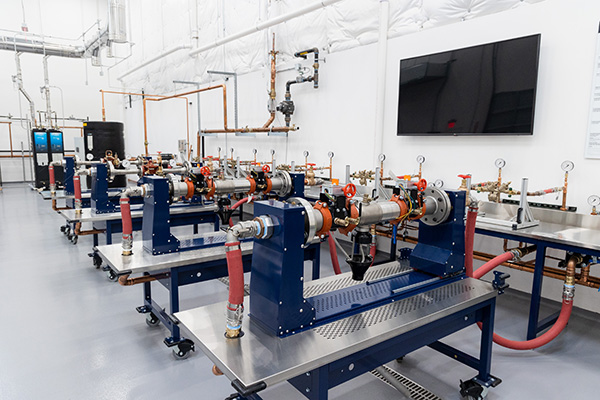

The 3,600-square foot Learning Center features an 800-square-foot classroom with space for up to 18 people, plus a 2,800-square-foot hands-on wet lab, featuring a number of Watts products, including the following:

- BLÜCHER HygenicPro Drains

- Leak Defense

- Lync Aegis W Heat Pump

- PVI Brigade; Conquest; Centurion Water Heaters

- Watts Automatic Control Valves

- Watts Big Bubba Water Filter

- Watts Cast Iron Drains

- Watts OneFlow/PVI AquaSolve Antiscale System

- Watts SentryPlus Alert Flood Protection System

- Watts/Ames In-Building Risers

- Watts/Ames/FEBCO Backflow Preventers

Products are also on display and in action in the building’s mechanical room showcase that is behind a glass wall alongside the entrance to the center.

Many of the other Learning Centers are purposefully located inside Watts manufacturing facilities so that they, too, serve as an extension of the classroom.

“There’s nothing better than bringing our customers in, training them in-person, taking a manufacturing tour and experiencing our people, our culture, and our products and solutions firsthand,” Gyorda says.

Watts opened its first Learning Center in North Andover, Massachusetts; (Watts’ corporate headquarters) in 2016; Woodland, California in 2016; St. Pauls, North Carolina in 2018; Burlington, Ontario, Canada in 2019; and finally in Fort Worth, Texas.

At the Fort Worth Learning Center, visitors can choose from a variety of courses including the following:

- Water Heaters / Boilers

- Automatic Control Valves

- Leak Detection Solutions

- Heat Pumps

- Backflow Prevention

- Water Pressure Reducing Valves

- Stainless-steel Drainage

- Cast Iron Drainage

- Water Quality Solutions

- In-building Risers

- Digital Mixing Solutions

- Smart & Connected Solutions

Watts Celebrates 150 Years

By John Vastyan

When Joseph Edwin Watts arrived in America in the 19th century, he found a country engaged in a spirited expansion of both its western territory and its eastern industrial base. At the time, America was a heroic land where an individual could make their own mark, profit by their talents and carve out a future of their choosing.

Watts was among the first of a group of workers who would remake New England’s powerhouse textile industry in Lawrence, Mass.; a new town that had been built on faith in American ingenuity to harness more effectively the immense power of the Merrimack River for modern industrial production. Earlier success in capturing the river’s water power had led to the founding of Lowell, Mass., which quickly became the showpiece of the American textile industry.

It was in Lowell that the water turbine was invented — a device that was far more efficient than old water wheels in translating the energy of falling water into the rotary power used throughout the mills. In 1845, a group of industrialists, investors and mill owners formed a corporation to establish an industrial center in Lawrence where no community had existed before.

The Essex Co., as the group was known, created a plan for an independent machine shop, which became the forerunner to Joseph E. Watts’ later enterprise. To deliver water from a well-designed and engineered dam in Lawrence, the group also constructed the North Canal.

In 1848, after nearly three years of work and a substantial investment in waterworks — including a large dam, and canal — Lawrence’s first mill was commissioned. Lawrence grew to a population of more than 12,000 by 1853.

After a brief move to New Hampshire in 1867, Joseph E. Watts had settled in at the Pacific Mills as a machinist. At the time, a machinist was a mechanical jack of-all-trades — machinists fabricated metal parts, adjusted and repaired the mill machinery, performed plumbing tasks and oversaw the great boilers used to produce steam for processing wool. Watts quickly proved he had a head for learning new skills.

Watts chose to leave the employ of Pacific Mills in 1874. He set up an independent machine shop in Lawrence where he subcontracted his work to the mills. The business flourished, so he shared in the growing wealth of the nation; his operations moved to larger and larger facilities. In 1893, Watts constructed a monumental, block-sized brick building in Lawrence. It was equipped with the latest up-to-date machinery, recognized as the best built and most completely equipped machine shop in Lawrence.

The textile mills of Lawrence, for which Watts supplied products, were the most advanced and complicated manufacturing concerns in the mid-and-late 19th century. Their sheer size made them pioneers in industrial systems we take for granted today — automatic sprinklers, fire-protection pumping systems and large, steam boiler heating systems.

Much of Watts’ success lay in his inventiveness. Sometime after 1881, Watts began to seek patent protection for his innovations, mostly related to pressure-reducing valves. Before his death in 1894, he had received a total of 18 patents for valves needed by the textile industry. Watts had managed to accomplish what individual inventors always dream of — he created a humble device that proved essential to many industries.

In essence, Joseph E. Watts had planted the seed for a control valve industry. The significance of Watts’ accomplishments was not lost on Robert F. Pickels, a Lawrence construction engineer. Pickels had overseen a machine shop employing 300 men and had worked as a draftsman and designer for the forerunner to the General Electric Co.

Pickels’ business partner, George W. Dodson, knew a thing or two about the residential plumbing and heating business. In May 1895, for an unrecorded sum, Pickels and Dodson purchased the Watts business, patent rights, buildings and goodwill from Amelia Watts, Joseph’s widow.

Pickels’ technical acumen and Dodson’s practical abilities were a good match for the new company. By September, the pair had quadrupled Watts’ volume of business and had doubled the workforce, expanding to two of the three floors of the new building Watts had erected in 1893, just two years earlier.

The Watts Regulator Co. still sold gravity-controlled regulators invented by Joseph E. Watts, but Pickels had capitalized on improved materials technology. New metallurgy made dependable and long-lasting metal springs available, and rubber processing had matured to the point where rubber gaskets had become reliable.

As a result, several new regulator valve designs incorporated both springs and rubber gaskets. These later versions were much smaller than Watts’ designs, which required lever arms and external weights. Because these regulators were small, they would fit into the limited space available for household plumbing and heating. In this way, Robert Pickels laid the groundwork for the next direction of the Watts Regulator Co.

After nearly a quarter century at the helm, Pickels put Watts up for sale. In the fall of 1918, a trio of Lawrence men each invested $25,000 to purchase Watts Regulator: Burchard Everett Horne; his uncle Herbert W. Horne; and a mutual friend, Norman Anderson. Within a year, Burchard Horne had acquired Anderson’s share of the business and soon purchased his uncle’s portion as well. The transfer marked a new era for Watts Regulator as a family-owned-and operated business.

Fast forward a few decades to the 1980s: the company began restructuring its management team while preparing for its first public stock offering, which finally took place at the end of August of 1986. The firms of Shearson Lehman Brothers Inc. and Donaldson, Lufkin & Jenrette Securities Corporation were the primary underwriters for the initial offering of 4.5 million shares of Class A common stock. Shares of Watts Industries, trading as WATTA on the NASDAQ exchange, were offered at $16.50 per share. Today, Watts is traded on the NYSE exchange under the ticker symbol WTS.

Perhaps one of the most significant undertakings for Watts was its response to the Reduction of Lead in Drinking Water Act, introduced in January 2011. The law stated that by January 2014, all U.S. water systems providing water for human consumption needed to use materials, devices and components meeting new “lead-free” requirements. The legislation had sweeping impact on the industry because bronze, which had been the industry standard, contains naturally occurring levels of lead.

Watts made the courageous and visionary decision to open a dedicated lead-free foundry, allowing Watts to control its own destiny in the U.S. and position the company as a trusted source for lead-free products.

Watts also took a leadership role in educating the industry about leadfree metals as a founding member of the “Get the Lead Out” Consortium. Not only did Watts need to construct a modern foundry, but it also had to reinvent thousands of products.

Having the vision to make bold decisions such as going public and investing in a lead-free future are just a few of the hallmarks of Watts’ legacy as an iconic industry leader.

Two Major Product Milestones

The T&P valve was revolutionary for the proper protection of hot-water supply tank systems. Domestic hot-water supply tanks and heaters had long been recognized as potentially dangerous, for the buildup of excess heat inside a tank that could lead to explosion. The initial solution to this problem was to equip domestic hot-water tanks with pressure relief valves. When the internal pressure built up beyond a certain limit, the valve opened to drain the heat-expanded water.

In 1935, the American Gas Association in effect rewarded Watts’ efforts by sponsoring an American Standard 221-22 for T&P valves. But this standard was not immediately embraced at the local level. Watts set to work making the case for water heater safety. More information can be found in their film, “Danger Explosion Lurks.”

Backflow is the reversal of the normal flow of water in a system. As an example, opening a fire hydrant outside a building can create a vacuum in the water-supply line, drawing water out of pipes back into the main supply. In December 1970, a Cincinnati winery left a water-supply valve open after flushing out wine fermentation tanks. During a subsequent fermentation, a diluted burgundy back flowed from vats into the city supply line and ultimately out of the kitchen faucets of nearby homeowners. The fermentation tanks were operating at a higher pressure than the city water system.

The creation of a complete line of backflow preventers marked Watts’ movement even further into the plumbing and waterworks industry. The company joined the American Water Works Association and the ASSE in order to participate in their code-making processes. ASSE set standards for each type of backflow preventer; Watts worked closely with the organization to ensure that its backflow preventers met or exceeded ASSE standards.

Growing understanding of the hazards of backflow also helped Watts’ stature in the industry. In 1974, Congress passed the Safe Drinking Water Act, which led to regulatory mandates for cross-connection control programs.

John Vastyan owns Common Ground, a trade communications firm based in Manheim, Pennsylvania.