Specifying the right fire sprinkler system for commercial applications can be a complex and challenging issue—not only because of the large number of lives at stake (especially in larger, high-rise structures), but also because of the size, design complexity, cost and potential liability associated with the project. That’s why it’s important to consider options carefully and objectively, weighing all the facts and dispelling any unfounded misperceptions.

For commercial applications, the two most commonly used materials are steel and chlorinated polyvinyl chloride (CPVC). Although steel has traditionally dominated the market, leading brands of CPVC fire sprinkler systems have been garnering market share at record rates in a wide array of commercial applications around the globe. As a specialty listed product, CPVC is approved for all light-hazard wet systems in accordance with NFPA 13, 13D and 13R.

Today, CPVC fire sprinkler systems can be found in high-rises, hotels, college dorms, schools and office buildings, and health care and assisted living facilities. They have proven to represent the smarter long-term investment for new construction and present an even stronger case in retrofits, which are rapidly growing in number as cities across the U.S. are redeveloping their downtown commercial centers and converting vacant space into mixed-use developments.

This article addresses just a few of the many comparative advantages of a CPVC fire sprinkler system and the solutions it brought to one multi-story retirement home.

Performance advantages

With their natural immunity to scale, corrosion and microbiologically influenced corrosion (MIC), CPVC pipe and fittings offer a long, low-maintenance service life that typically exceeds that of traditional metallic systems which are vulnerable to the effects of corrosion. Made of a high-performance thermoplastic, CPVC fire sprinkler pipe is manufactured to Iron Pipe Size (IPS) SDR 13.5 dimensions and rated for continuous service of 175 psi at 150°F.

As a comparatively newer material, CPVC fire sprinkler systems have also been subject to more stringent performance testing than various metallic systems that were grandfathered into many codes. Hydrostatic pressure tests and pressure cycling tests are just two examples that CPVC piping systems undergo in order to obtain their FM approval and UL Listings.

Cost advantages

In addition to stable, highly competitive material costs, what truly makes CPVC a more economical solution is the labor savings. Some contractors, in fact, have reported as much as a 50 percent total cost savings over steel, depending on the size and configuration of the project. Such savings are a direct result of the fast and easy solvent welding joining process, which results in a permanent chemical bond that is actually stronger than the pipe or fitting alone.

When AEGIS Fire Systems, a California-based fire protection services provider, was tasked with a five-story retrofit project at the Jewish Home of San Francisco. The BlazeMaster Fire Sprinkler Systems offered the solution they needed for an installation that minimized the impact to the home’s operations.

Jewish Home houses approximately 300 residents and is entrusted by numerous families to ensure their loved ones’ time there is safe, comfortable and secure. Knowing the sensitive nature of the project, AEGIS knew that steel, with its time consuming and noisy installation, would pose many problems. The fire sprinkler systems’ one-step solvent-welding solution for joining pipes and fittings allowed each floor of the complex to be completed quietly and quickly, which helped cut down on time and labor costs.

Another factor contributing to the overall cost savings of CPVC pipe and fittings is the hydraulics of the CPVC system. The Hazen-Williams C factor is used to describe the amount of friction loss that is encountered when water flows through a pipe. Steel pipe has a C factor of 120 compared to the 150 C factor of CPVC pipe. This higher C value indicates that CPVC pipe has less friction loss, which often allows for pipe downsizing of at least one size smaller in diameter than steel. The differential between the C factors increases with time as a result of corrosion on the interior wall of the steel pipe creating greater friction. The corrosion of steel pipe and fittings can also lead to clogged heads and premature failures which increase the long-term costs of a steel fire sprinkler system installation.

One misperception worth addressing is the impact of hangers on the overall cost of installing a CPVC fire sprinkler system. Not so long ago, it was argued that since CPVC pipe is more flexible than steel, more hangers are required which added to the cost of the project. While it is still true that hanger spacing is often different between CPVC and steel systems, today there are more hanger designs, fastening technologies and more competitive pricing. Therefore, installers who frequently install CPVC fire sprinkler systems are finding the cost differential to be negligible and not significant enough to offset the overall cost advantages.

Installation advantages

Installers typically prefer CPVC fire sprinkler systems because the material is lightweight and easy to maneuver on the job site. With a CPVC system, last-minute changes can easily be accommodated with on-site fabrication. With the lighter weight also comes greater installation flexibility, since systems can be installed on the ceilings or the walls. And, since the pipe is less rigid than steel, it more easily accommodates tight spaces and facilitates working around walls and soffits.

“We wanted to be very considerate of getting in and getting the work done as quickly as possible,” said Dave Karrick, of AEGIS Fire Systems. “These are people’s loved ones. I thought about how I would want my grandmother to be taken care of in a similar situation.”

The installation advantages of a CPVC fire sprinkler system are magnified in retrofit situations.The installation process is quiet, neat and fast and does not require the use of heavy equipment, oils or a welding torch. That means less downtime and less disruption to building occupants. In many cases, retrofits can be completed without having to relocate occupants for extended periods of time— which was important for the residents of the Jewish Home.

“We really were shocked at the minimal noise caused by the construction,” said Oleg Korsunsky, environmental health and safety manager at Jewish Home. “With any sort of construction project, you expect noise to become a problem, but with our new fire sprinkler system, there was practically zero noise to speak of. That was very valuable to us.”

For another example, in the case of a college dorm, when retrofits must be completed before the start of the next semester, a CPVC fire sprinkler system offers an advantage. Some colleges have completed a CPVC fire sprinkler system retrofit while the students were in class with minimal disruption.

Environmental advantages

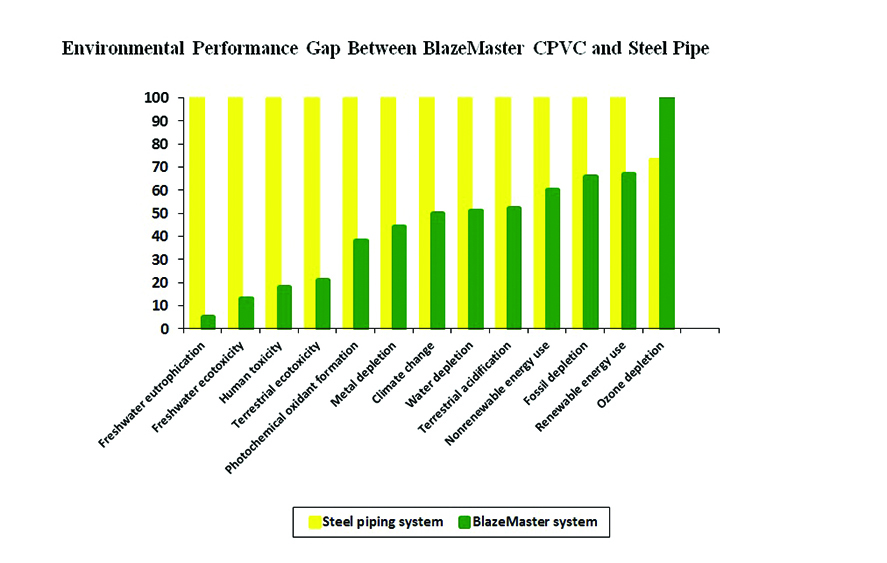

In our green-conscious society, sustainability is a factor in most nearly all commercial projects today. A generally accepted means for assessing the sustainability of a product is through a Life Cycle Assessment (LCA), which studies the environmental impact of material using a cradle-to-grave approach.

An ISO-compliant, peer-reviewed LCA conducted by Environmental Resources Management Ltd. (ERM) compared the environmental impact specifically between CPVC fire sprinkler pipe and fittings and steel. The results showed CPVC to be sustainable based on the study of 13 environmental impacts, including:

- metal depletion

- fossil fuel depletion

- terrestrial acidification

- freshwater eutrophication

- climate change

- ozone depletion

- human toxicity

- freshwater ecotoxicity

- photochemical oxidation

- terrestrial ecotoxicity

- water depletion

- energy consumption (non-renewable and renewable)

Conclusion

It's important to realize that today, specifiers and contractors do have choices when it comes to piping materials. CPVC has been proven, through both lab tests and actual installations, to offer greater cost efficiencies, as well as superior reliability over the long term. It is no wonder that it is becoming the material of choice for commercial fire sprinkler systems in a wide array of commercial applications around the globe.

Knurek is marketing manager for BlazeMaster Fire Sprinkler Systems of The Lubrizol Corporation.