Systems Architecture for Zero Net Energy Performance in Multifamily and Office Buildings, Part 2

Ventilation options with best practices for implementing high-mass radiant floor cooling.

This is the second part of a three-part series focused on zero net energy (ZNE) performance in multifamily and office buildings. This part focuses on ventilation options with best practices for implementing radiant floor cooling. To take advantage of water as a transport medium for heating and cooling, heating and cooling must be separated from ventilation. Traditional forced-air designs assume a ventilation rate added to the peak heating or cooling loads to size ductwork.

A best practice is to separate heating and cooling loads from ventilation and supplemental cooling, which is handled with much smaller ducts or underfloor air distribution systems (UFAD). Primary heating and cooling is implemented with high-mass radiant heating and cooling, which, by definition, incorporates water as the transport medium. Ventilation is provided by a dedicated outdoor air system (DOAS) that can use the same hot or chilled fluids in hydronic coils to condition air.

Due to time of day or seasonal occupancy, office buildings, dormitories, barracks and multifamily residence living spaces are ideally configured as zones within the larger building footprint. Most commercial buildings are designed with a central HVAC system and then the engineer attempts to create smaller zones to serve occupied spaces.

While this appears straightforward, controlling air temperature and output volume when zoning a forced-air system is more challenging than it appears; the results rarely provide optimal user comfort and indoor air quality. Scaling a large air system back to heat or cool a few zones is limited by the minimum output of the central HVAC heat pump.

Consider a residential application with a 5-ton, two-stage air conditioner (a cooling-only heat pump) where only a few smaller rooms call for cooling. The air conditioner’s minimum output on a low-speed compressor is typically 60% of the air conditioner’s rated output at high speed. Therefore, the minimum output is 3 tons. The occupants experience short-cycling of the air conditioner and inefficient operation when less than 3 tons of cooling is needed.

While this can be addressed by heat pumps with variable-speed compressors that can scale back to 10% of rated capacity, many designers argue that the capital cost of this equipment makes the solution unaffordable. Scale this to a large office building and the problem is exacerbated.

Zoning: TABS and High-Mass Hydronic Systems

Distributing smaller variable-speed heat pumps for primary heating and cooling is one means to attain ZNE performance in buildings under 50,000 square feet; however, this approach is rarely implemented due to the initial capital cost. When used for supplemental cooling and ventilation, the distributed heat pump model works well in any size building.

When primary heating and cooling are provided via a high-mass hydronic system, the zoning limitations previously described with forced-air appliances do not apply. Using a high-efficiency central plant for hot or chilled water, adding a zone is simply a matter of adding a thermostat to the desired zone and a zone valve to the radiant distribution panel for the buildings.

For this reason, thermally activated building systems (TABS) and similar hydronic technologies are well-suited for zoning buildings with daily or seasonal occupancy, such as multifamily and office buildings. The individual zones receive hot or chilled water from a central thermal storage, such as storage tanks or campus heating and cooling loops.

Efficiently producing hot or chilled water in a central plant is a separate process from delivering that hot or chilled water to heating or cooling individual spaces. Using a hybrid solution versus all forced-air systems, distributed heat pumps in this role make sense as both technically feasible and affordable.

In his book, “Thermally Active Surfaces in Architecture,” published in 2010, Kiel Moe promoted this hybrid solution, separating heating and cooling with high-mass structures from ventilation using forced air. He documented dozens of buildings in Europe using this architecture, which has now become a standard for ZNE buildings worldwide.

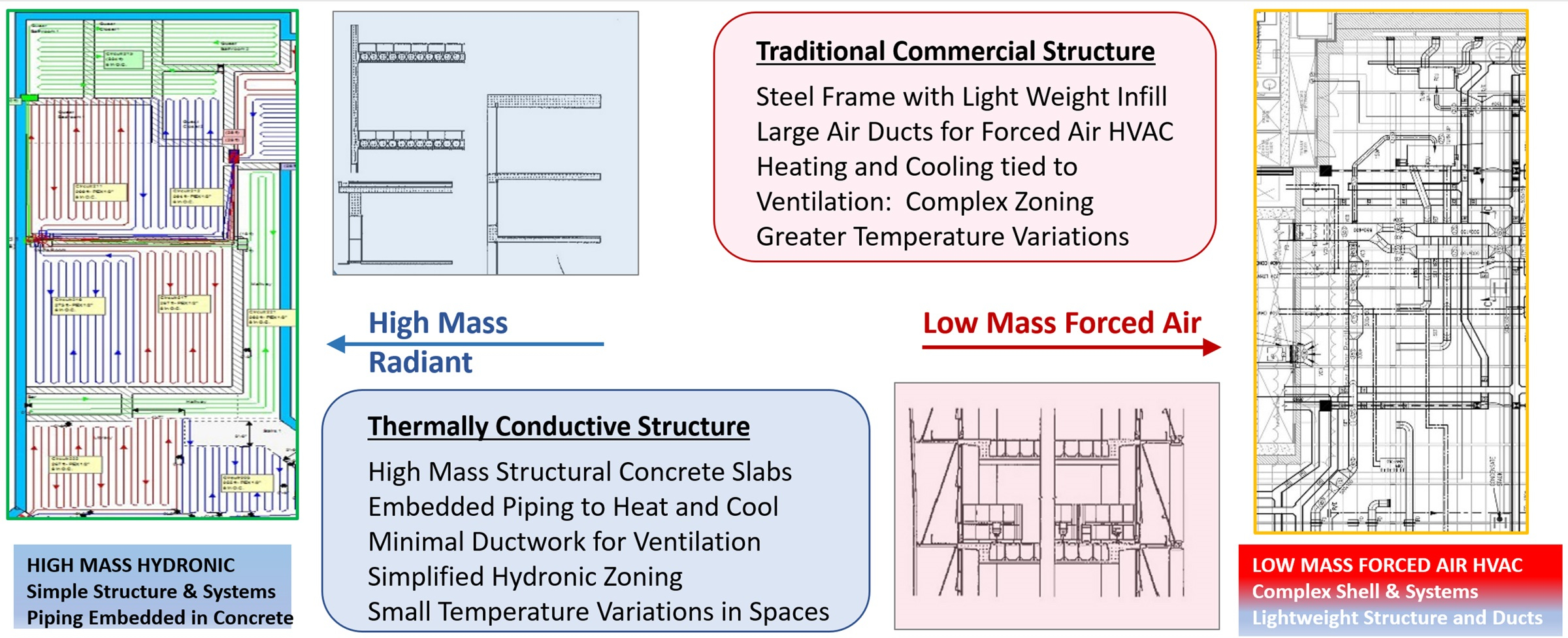

Using a graphic like Figure 1, he demonstrates in plan and elevation the simplicity and elegance of high-mass hydronic structure design versus traditional low-mass, forced-air buildings.

Since the book was published, ventilation and supplemental cooling technologies have evolved, moving away from variable-air velocity systems for ventilation to DOAS with UFAD for ventilation and supplemental cooling. UFAD makes sense for high-mass structural concrete floors/ceilings, as shown in the elevation view at left in Figure 1.

Manufacturers of DOAS units for preconditioning ventilation air are moving away from cooling towers using large amounts of water for evaporative cooling. They now incorporate geothermal heat pumps with variable-speed compressors or hydronic heating and cooling heat exchangers for higher energy efficiency and lower maintenance costs. For most climates, the DOAS can effectively provide the supplemental cooling needed with high-mass radiant cooling systems.

When TABS cannot meet cooling demand, distributing smaller 3- to 6-ton water-to-air, variable-speed heat pumps throughout the building is a best practice in that automatic humidity control is included with the heat pumps from the manufacturer. The same water used for radiant cooling (around 58 F) is also used for the source water to these distributed heat pumps.

This eliminates separate piping to a ground-source heat exchanger with associated maintenance issues, such as maintaining antifreeze in high-volume systems.

Radiant Cooling and Heat Transfer

Given the cavalier inclusion of radiant cooling with radiant heating to this point, a reasonable question is, “How exactly does radiant cooling work, and how do you control radiant cooling with TABS without the risk of condensation in the structure?”

To answer this, we go back to the discussion of heat transfer. Radiant cooling is not cooling as much as it prevents the mean radiant temperature of the space from rising. Unlike convection or conduction, solar radiation enters the space as short-wave radiation (visible light, think sunburn) and is converted to long-wave radiation (think microwaves).

The elevated temperatures of surfaces within the space heat the air through convection and conduction and warm occupants through radiation. High-mass radiant floor cooling is most effective, removing solar and lighting heat gains from radiation; direct exposure to sunlight is 30 BTU/hour/square foot, whereas indirect cooling through conduction and convection is 15 BTU/hour/square foot.

A high-mass, radiant-cooled floor preemptively cools the space by absorbing heat from higher-temperature surrounding objects, surfaces or people in the space. This delivers higher thermal comfort and efficiency.

Anyone who has visited a cathedral in Europe on a hot summer day has experienced this phenomenon. While the cathedral most likely does not include forced-air cooling, at noon, the interior feels cool. Overnight cool air circulating in the space removes heat from the multiple tons of structural thermal mass.

The next day, with very hot outdoor air temperatures, tourists walk comfortably in the interior. Their bodies radiate heat to the interior as heat moves from hot to cold. Their bodies sense this lower mean radiant temperature within the first five feet from surfaces, even though no air conditioning cools the air in the structure.

This is particularly relevant to the energy efficiency and comfort of radiant floor cooling in structures with high ceilings, as only the first few feet of the space experienced by the occupants need to be conditioned.

High-mass radiant ceilings do not include this benefit. While they are more effective in removing heat from the occupied volume of space due to the temperature differential between the surrounding air (hotter at the ceiling than the floor), the positive impact on occupant comfort is less due to the distance of the ceiling to the occupants.

While the controls associated with radiant heating systems are well-established and quite simple, high-mass radiant cooling requires precise dew point control to prevent condensation on cooled surfaces. A heating-only radiant system uses an aquastat to control the supply water temperature and a thermostat to control demand for the relevant zone.

For more precise control, some manufacturers offer thermostats with slab temperature sensors to augment the air temperature sensed within the thermostat. A radiant cooling system requires calculating the dew point of the air at the radiant-cooled surfaces using the temperature of the cooled surface and humidity of the space containing the cooled surface. Ideally, a slab temperature sensor is incorporated to shut down the system if the radiant-cooled surface drops below the dew point to prevent condensation.

Technically, radiant cooling refers to high-mass TABS, hydronic fan coils or chilled beams. “Hydronic cooling” simply means providing cooling with chilled water. Unlike TABS, hydronic fan coils and chilled beams may use chilled water below the space dew point if equipped with condensate drains. A forced-air fan with a hydronic coil that uses hot or chilled water to heat or cool is known as a fan coil unit.

Chilled beams can be active using a fan or passive using natural convection to circulate air. Without condensate drains, chilled beams can only operate properly with water supplied above the dew point to prevent condensation on the coil.

In that application, it is imperative to calculate the dew point based on the temperature and humidity on the surface of the chilled beam. Many failed designs have used the dew point of the building, such as returning air to a DOAS for controlling the supply water temperature to the chilled beam. These designs failed to acknowledge that the localized zone dew point with high ceilings is significantly higher.

Thermal Storage: Geothermal or Water-to-Water Heat Pumps

Heating and cooling with a water-source or geothermal heat pump requires thermal storage, as shown in Figure 2. This is not required with boiler heating and cooling tower chilled water, which are plumbed in series with the heating/cooling appliance.

A chiller is essentially a cooling-only water-to-water heat pump. Manufacturers recommend 1 gallon of thermal storage (fluid in continuous circulation or a tank) for every 1,000 BTUs of capacity to prevent short-cycling of the heat pump. A geothermal water-to-water heat pump has this storage capacity in the ground-source heat exchanger yet requires thermal storage on the load side, which supplies the radiant heating and cooling system.

The control parameters for radiant cooling are radiant floor temperature, space temperature and space humidity used to track dew point, whereas heating requires only supply water and space temperature control. While the chiller may be configured to supply a campus with chilled water below the dew point, this chilled water must be mixed or flow-limited to deliver water above the dew point to the zones, which use radiant-cooled floors or ceilings.

A best practice for supply water temperature control is to mix the campus chilled water with the radiant return water to keep entering water temperature above the dew point. This approach is more efficient than mixing campus chilled water with campus hot water to control the entering water temperature.

As noted in the lower left corner of Figure 2, the efficiency of the system is driven by the efficiency of the heat pump supplying the hot or cold water with the coefficient of performance (COP) ranging from 1.0 to 3.0 for an air-source heat pump/chiller, and a high limit of 5.0 for a ground-source heat pump in optimal operating conditions. While relatively efficient compared to a boiler with a COP less than 1.0, this heat pump configuration will not deliver the efficiency required for ZNE performance.

Zero net energy buildings require a systems architecture delivering a seasonal performance factor exceeding 10 — twice the performance of state-of-the-art heat pumps today.

Part 3 of this series will focus on dramatically improving heat pump efficiencies with source process heat exchangers and conclude with a review of the overall ZNE architecture encompassing the technologies discussed in this series.

Albert Wallace serves as president of Energy Environmental Corp. He is a Certified Geoexchange Designer and Certified Energy Manager. He is a member of ASHRAE, an American Institute of Architects associate member, and a certified trainer and installer by the International Ground Source Heat Pump Association. For more information, visit www.energyhomes.org.