It has been more than 20 years since the National Fire Protection Association’s NFPA 13, Standard for the Installation of Sprinkler Systems, 1999 edition, mandated the use of alpha-numeric markings on all sprinklers as a means of identifying their operational characteristics. These markings, now commonly referred to as sprinkler identification numbers (SINs), are nearly ubiquitous across Canada, the United States, and several other nations where NFPA 13 has been adopted.

Yet many who rely upon the SIN as part of their roles in the design, installation, inspection or maintenance of sprinkler systems are often unaware of the benefits and history behind this simple system.

The Sprinkler Identification Number

A SIN is a four-to-six-character alpha-numeric code that includes one or two capital English letters followed by three or four numbers and is physically applied to the sprinkler, often on the deflector, although NFPA 13 does not require it to be placed there. Typical examples of a SIN include L414 or BD1423.

The SIN letters identify the sprinkler manufacturer. The three or four numbers that follow are then provided by the manufacturer in a manner that best suits their needs. Some manufacturers use the numbers to represent specific sprinkler characteristics within their product lines; others use them strictly as a cataloging number. Figure 1 illustrates the physical application of the SIN to several sprinkler types.

|

|

|

But regardless of how each manufacturer chooses to manage their SIN program internally, the goal of this flexible system is the same: to ensure proper selection and application of each sprinkler.

What Prompted Development of SINs?

The fire sprinkler industry is not often thought of as being “disruptive” or radically innovative. And to be fair, the great majority of the sprinklers installed today do not look all that different from some of the original patented designs. Moreover, through the first half of the 20th century, the majority of sprinkler head evolution was limited to improvements in manufacturing, reliability and quality. Not exactly sexy stuff.

However, by the 1950s, with ongoing loss prevention research and an expanding record of successful fire control, the fire sprinkler industry reached a pivotal conclusion: fire sprinkler discharge directed toward the source of the fire is simply more effective. That led to the development of the 1/2-inch K-5.6 (K-80) standard spray upright (SSU) and pendent (SSP) sprinklers that became a basis of design that is still widely used today.

The shifts in industrial practices in the 1970s, particularly warehouse storage, and a developing interest in sprinklers as a life safety tool revealed that the “standard spray” sprinkler had limitations when used to protect the evolving challenges and new fire safety objectives.

The sprinkler industry began developing new products incorporating faster response, specialized discharge characteristics and often larger nominal sizes that created enhanced capabilities better suited to protecting the evolving hazards. Yet, as these new products demonstrated the successful application of fire sprinkler technology to meet the challenges, they were creating a new set of problems for practitioners out in the field.

Up to this point, the SSU and SSP sprinklers of the past had been largely interchangeable if the fitters selected the same orientation and temperature ratings. But these new, more specialized sprinkler innovations required designers, installers, regulators and maintainers to readily identify and confirm that the right sprinkler was selected and installed properly.

NFPA 13 (1994) sought to address the expanding variety of sprinklers by requiring manufacturers to provide a means of visual identification that included the installation of pintles to the deflectors, adding markings on the sprinkler frames, and mandating that sprinklers with larger orifice sizes employ larger thread connections (see Figures 2 and 3).

However, this method of marking and identifying sprinklers proved to be largely unworkable as many of the new sprinklers often incorporated more than just one feature outside of what had once been considered standard. There had to be a better way.

During the drafting cycle for the 1999 edition of NFPA 13, the Sprinkler Committee conceived a coded numbering methodology that would permit the identification of key sprinkler performance criteria (K-factor, orientation, responsiveness, etc.) that they envisioned could be uniformly applied across the entire fire sprinkler industry. However, it quickly became clear that such a highly structured coding system would not be workable.

There were already significant variations between manufacturers where their new specialized products made it all but impossible to codify. And that was before trying to create sufficient room within that system to account for future innovations, obsolescence and any current or future differences in the product approval standards.

As a result, the committee limited the application of the unique alpha-numeric designations to key differences in sprinkler performance, such as orifice size, response classification, spray pattern characteristics, maximum working pressure, etc. This narrowed scope also permits manufacturers to use the same SINs for groups of products that had only minor variations in attributes such as finishes, activation temperature ratings or threaded connection types.

Yet, the system allows each manufacturer to develop and employ a numbering system that works best for it. For example, Model AB120 could be one manufacturer’s standard response K-5.6 (K-80 metric) upright spray sprinkler, while Model BC120 could be another manufacturer’s K-14 (K-200 metric) early suppression, fast response pendent.

SIN Today

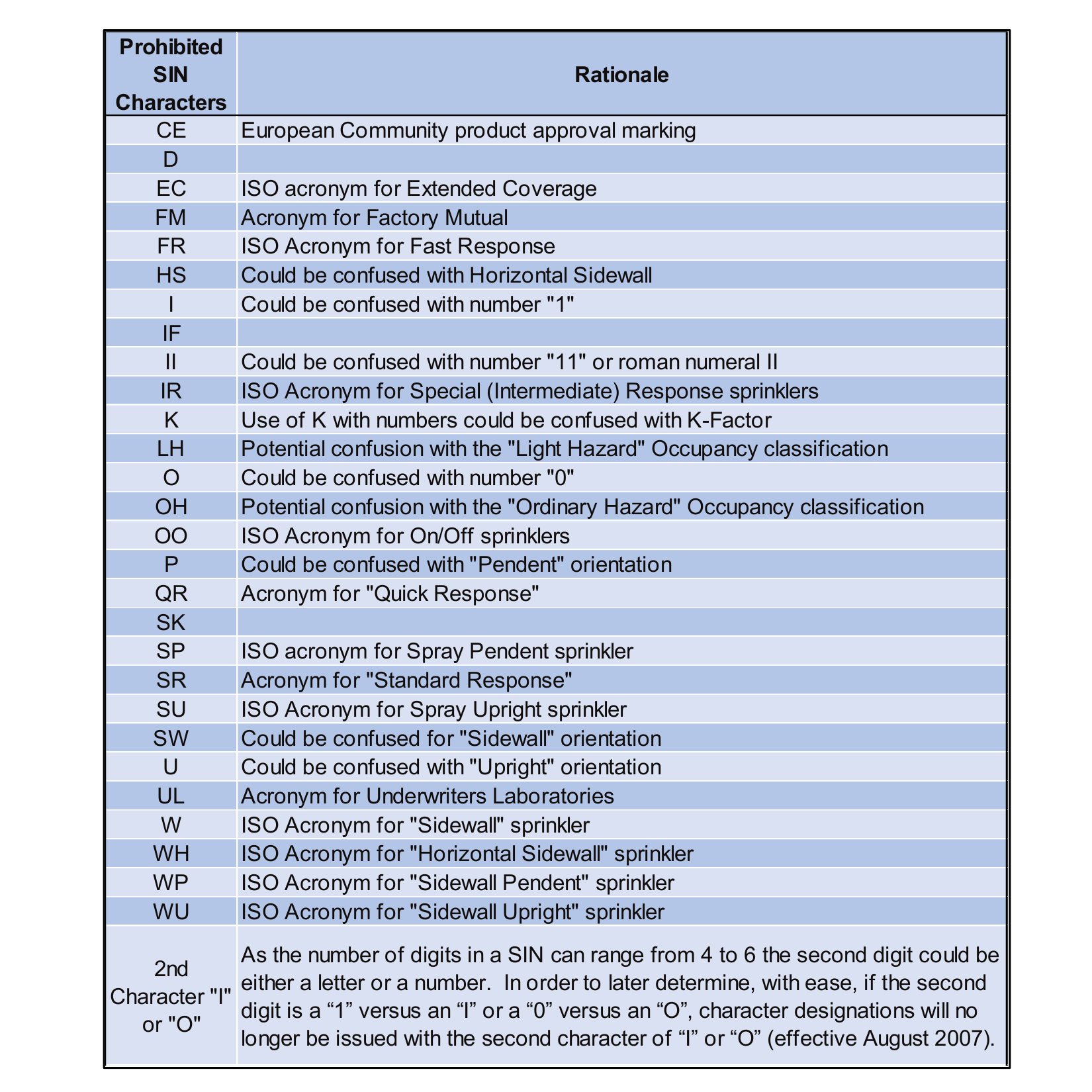

Sprinkler manufacturers register one or two letter codes with the International Fire Suppression Alliance (IFSA), which serves as the industry clearinghouse for this program. However, there are some limitations. First, some character sets are prohibited because their use could potentially cause confusion if used in conjunction with established industry acronyms and abbreviations (see Figure 4).

Second, once a SIN character combination has been registered and applied to a sprinkler, that character set becomes the permanent property of the corresponding manufacturer. Third, manufacturers are limited to a maximum of two-letter character designations.

And while that remains the current policy, IFSA monitors changes and consolidation in the fire sprinkler industry that has resulted in some registered character sets becoming dormant while others have been accumulated by manufacturers through corporate acquisitions.

Such changes are routinely updated on the IFSA website (www.firesprinkler.global) so sprinkler professionals can more easily identify the originally registered manufacturers and, when applicable, their successors.

SIN’s Future

As of March 2023, there have been 132 SIN letter-number combinations registered with IFSA. Of these, 73 are in active use with sprinklers in production. They are listed by UL Solutions or approved by FM Approvals, with several others currently in the process of obtaining product certification.

Historically, there are about four new SIN character registrations every year. A full list of SIN character registrations can be found at www.firesprinkler.global/sin-database.

These trends will almost certainly continue. The fire sprinkler industry is still growing, particularly as nations around the world continue to expand the use of sprinkler protection within their building codes. And there will certainly be new manufacturers and further innovation in sprinkler technology as well.

After 20 years, this simple system is serving us well: permitting designers, installers, maintainers and regulators to readily identify sprinklers by manufacturer and performance characteristics. This, in turn, helps ensure the sprinklers are properly installed for everyone’s mutual safety.

Paul Sincaglia is the managing director of the International Fire Suppression Alliance.