So many different types of geothermal exchangers are available that it can be a challenge to identify them all and then select which one or more will be best for your application. We’re going to focus on aquifer thermal energy transfer (ATET) in this column.

An aquifer-based thermal energy transfer system uses a non-consumptive water well. Non-consumptive is the key word here. Most jurisdictions are quite friendly to this type of system. However, it can be confusing to some of the authorities having jurisdiction in various locations. You can see a depiction of several types of exchangers in the header image, with the aquifer coupled system highlighted.

Site geology and groundwater (hydrogeology) have an influence on the feasibility and cost-effectiveness of a geothermal exchange system. The subsurface must be understood. This column relates some of the caveats and facilitates the protection of groundwater resources while ensuring the optimal performance of ATET. Always use an experienced and licensed geologist and hydrogeologist, as well as experienced drilling contractors on the design team.

Numerous types of subsurface opportunities are available for heat transfer. An aquifer is typically an excellent opportunity when it has ample volume and good advective flow. An aquifer is a body of permeable rock that can contain or transmit groundwater. Sometimes the water contained in an aquifer flows in between granules of sand; in other situations, aquifers look like Swiss cheese with cavities large enough for a house.

Most people think of an aquifer as an underground lake, river or other body of water. Aquifers can be confined or communicate with other aquifers, lakes, the ocean, etc. All these factors can influence the performance and capacity of an ATET system.

With an aquifer-based exchange system, the system pumps water from an abundant aquifer and runs that earth-temperature water through exchangers in the mechanical room, thus providing a heat source and a heat sink for the heating and cooling equipment that it serves. Some of the names under which this technology is also known include:

Pump and injection;

Pump and dump*;

Class V air-conditioning wells (Class V);

Aquifer thermal energy transfer (ATET);

Aquifer thermal energy storage (ATES).

* The “pump and dump” name implies that water is pumped from an aquifer, then dumped to another location, such as surface water or a storm sewer. This is illegal in most jurisdictions. Usually, when someone uses this terminology, they are speaking of ATET but don’t know to differentiate. The term used by most jurisdictions is “non-consumptive heat pump and air-conditioning return wells.” You can see that in this EPA report on the same topic: https://bit.ly/3iyltlq.

ATET often has the most benefit in large capacity systems adjacent to or above abundant aquifers. Properly engineered ATET systems can provide fantastic thermal exchange capacities with relatively few production wells.

In designing a system that uses an aquifer for heat transfer, it is important to follow several engineering standards to maintain good practice. Some of these include:

A thorough hydrogeological study (a test bore is often required);

A thermal energy communication study (heat crossover between well points);

A thermal energy influence study (to adjacent properties);

A water-quality study;

Design for Needs + 1 (redundancy);

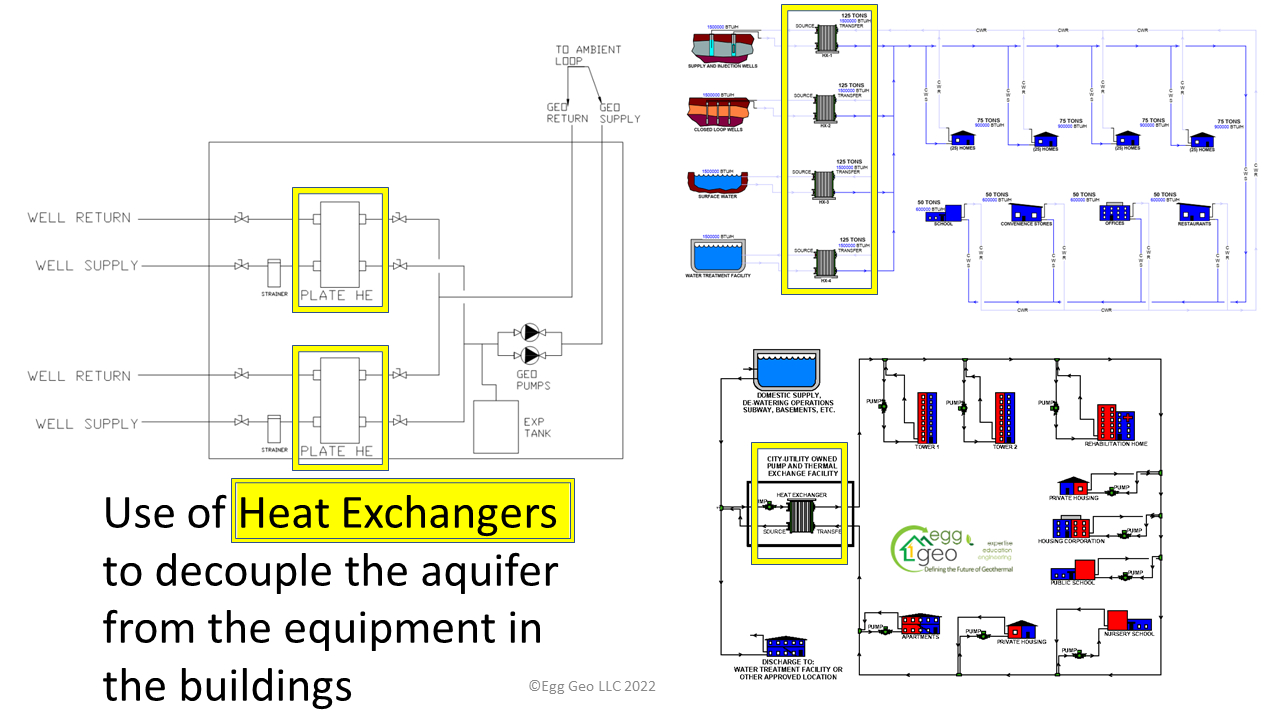

Isolation exchangers to decouple the ATET wells from the building or thermal energy network; see Figure 2.

Cooling Tower Elimination

As with many drought-distressed areas, the Las Vegas Valley Water Authority and the Southern Nevada Water Authority are beginning the process of eliminating evaporative cooling towers from new construction starting in 2024 (http://bit.ly/3Cgr72D).

With these types of restrictions coming into the market, we need real solutions to replace cooling towers while at the same time keeping the energy efficiency reasonably good. ATET systems fill that niche many times.

We are receiving increasing reports of building owners seeking to remove cooling towers because of the costs and liabilities associated with chemical treatment and prevention of Legionella outbreaks. It is common for buildings with cooling towers to have instances each year requiring chemical remediation to get the cooling tower back into safe standards of conformity.

Increasingly, health-care facilities decide that they’ve had enough, and they move forward with engineering a solution to be able to turn off the cooling tower and leave that as Needs + 1. In other words, if needed, they can turn on the cooling tower while the ATET system is being serviced (see Figure 3).

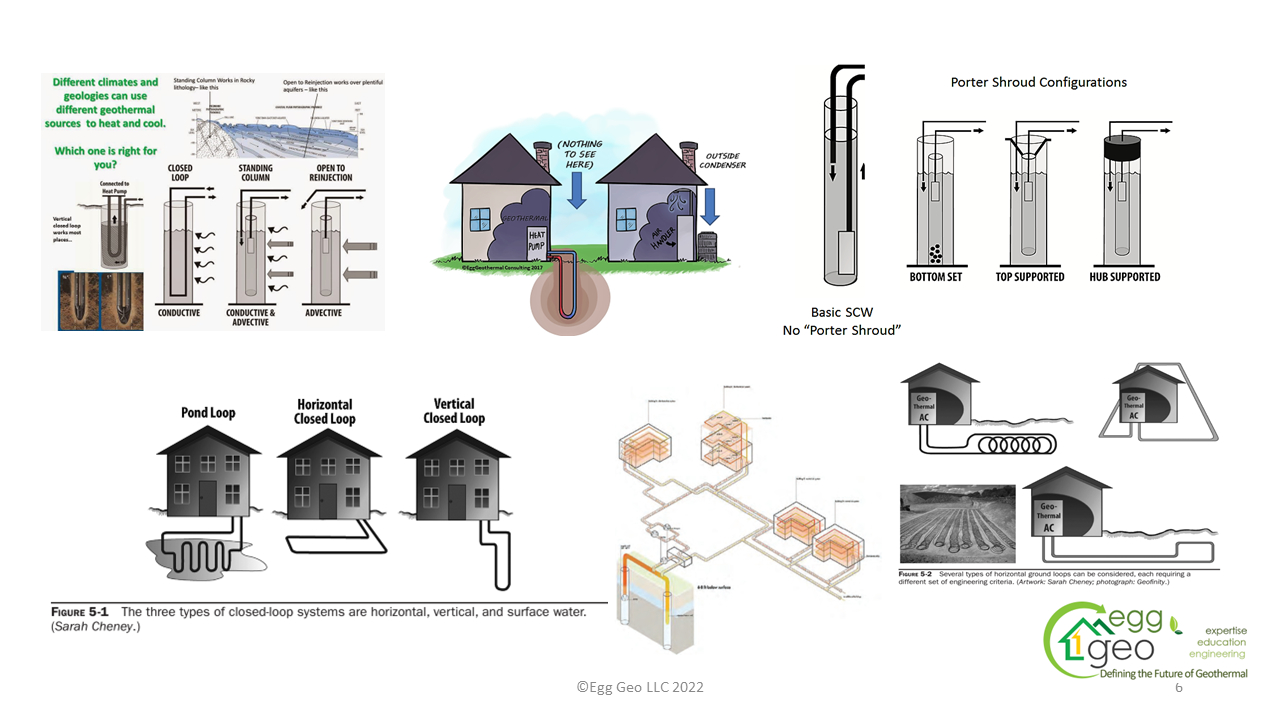

So far, we have spoken of ATET using well doublets, which is to say that there must be two holes drilled to complete the circuit. Two other types of geothermal exchange that do not need well doublets are:

1. Standing column wells (SCW).

2. Dynamic closed loops (DCL).

With an SCW, one large diameter hole is bored and water is drawn into the building via a pipe in the middle of the borehole called a Porter shroud. After the exchange is complete, the same water is injected into the annulus, which is the area outside of the Porter shroud.

In a DCL, a long, tubular exchanger (called a downhole exchanger) is placed under the mean water level and connected to the closed-loop equipment inside the building. The downhole exchanger is connected to a submersible pump, forcing groundwater through the downhole exchanger. It creates remarkable heat transfer capacity in one hole while protecting the aquifer and the heat pump equipment from ever touching the heat pump equipment.

Geothermal Exchange Configurations

We will share a depiction of the main types of geothermal exchange and suggest you keep this column and images nearby so you can consider all the options the next time you have a geothermal project.

There are seven general geothermal exchange configurations, and each one of them has a purpose and a place for their proper application. Five of them require a driller:

1. Closed-loop vertical exchange. Can be configured in two-pipe, four-pipe, concentric and many more adaptations.

2. Closed-loop horizontal exchange. Can be configured in many various ways to apply open trench-based exchangers.

3. Closed-loop pond/lake/ocean. These can be configured to use fabricated plate exchangers or polyethylene pipe arranged in the body of water.

4. Closed-loop energy piles. Similar to closed-loop vertical exchange, these can be adapted in many ways.

5. Open standing column well. Primarily allows for a reduction in boreholes, allowing for a smaller footprint. Needs specific geology (competent bedrock).

6. Downhole dynamic closed-loop exchanger. A tubular heat exchanger is placed in the borehole, allowing for the compounded benefits of closed-loop and open-loop systems.

7. Open Class V well doublets. Primarily allows for a reduction in boreholes and a smaller footprint. Needs specific geology (abundant aquifer). Great for large-scale applications in hot and humid climates (cooling-dominant).

Please note that all these geothermal exchange types can eliminate the need for cooling towers, saving millions, even billions of gallons of potable water each year. These technologies eliminate the need for boilers and related combustion heating, eliminating greenhouse-gas (GHG) emissions on-site.

Greenhouse-Gas Emissions

Whatever your location, building type, budget or goals, geothermal heating and cooling will likely do more for your efforts to reduce GHG emissions than any other technology. And geothermal works in sync with other technologies, reducing power consumption, eliminating combustion heating and improving resilience. When you apply geothermal first, everything else will fall into place.

Geothermal heat pumps provide the only reasonable solution to heating without combustion. Most of the time, a driller is needed to complete the installation. And what many folks don’t realize is that it’s clean and renewable solar energy we’re pumping out of the Earth.

Curious about what will work for your application? Check with the International Ground Source Heat Pump Association (www.igshpa.okstate.edu), the Geothermal Exchange Organization (www.geoexchange.org), or email me at [email protected].