As local utilities continue to drive the adoption of renewable energy sources on their electrical grids, greenhouse gas emissions from the operation of heat pump water heaters will continue to decrease. As was covered in Part 1 of this heat pump water heating series, understanding heat pump performance relative to source temperature and leaving water temperature is key to delivering high-performance systems (http://bit.ly/3iUQ2lL).

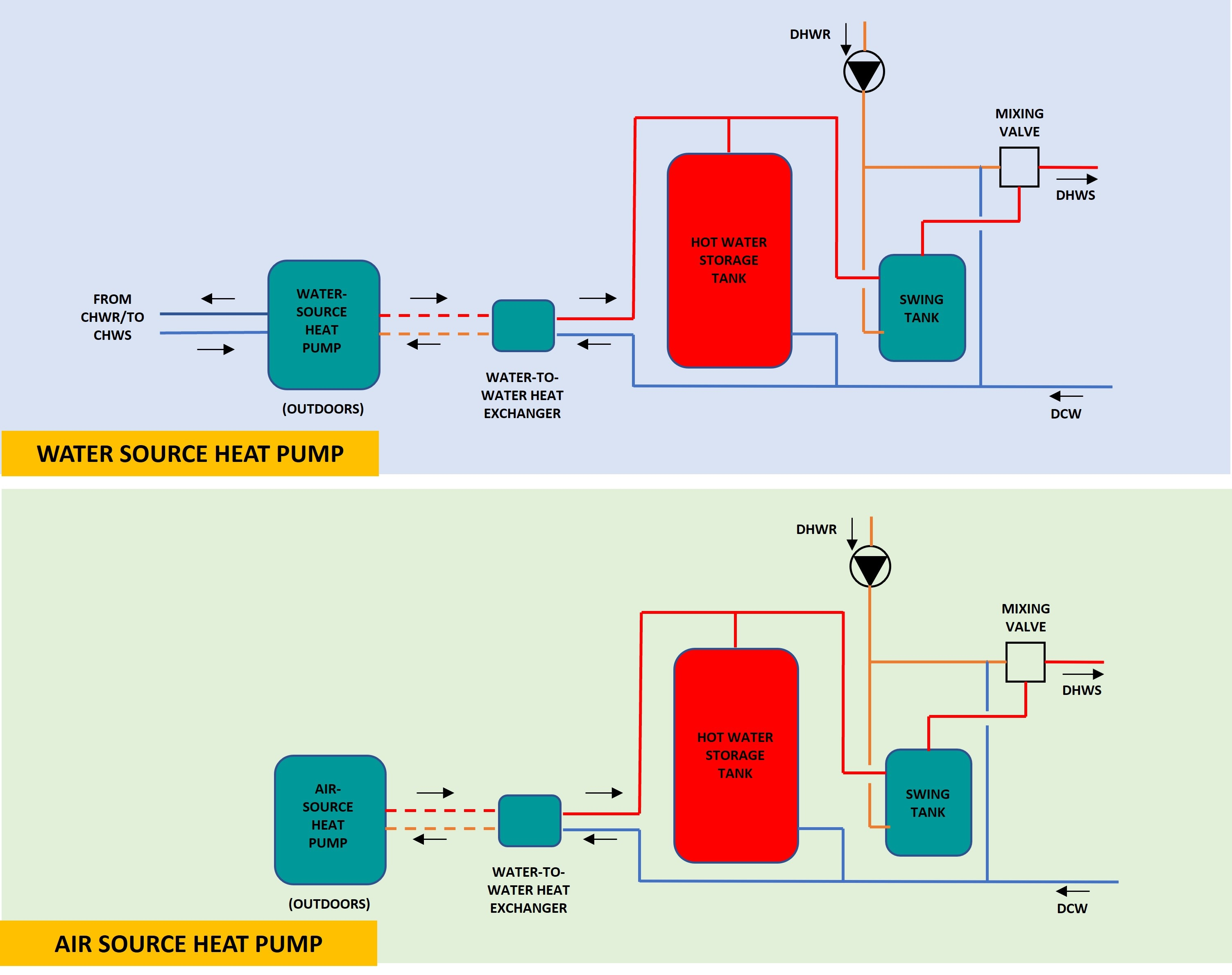

Once the design team determines the best heat source for the heat pump (ambient air, water, ground or even sanitary wastewater), the next step is determining the type of heat pump and matching piping arrangement with the hot water storage.

Two types of heat pump water heating styles are used in central heat pump water heating systems: multipass and single-pass. This nomenclature refers to how often the DHW will pass over the heat pump’s condenser coil heat exchanger before it reaches its final desired temperature.

In multipass heat pumps, which are typically R-410a refrigerant-based heat pumps, the heat pump pumps cold water from the storage tank and passes over the condenser coil in successive cycles. Each time, it lifts the water temperature in small steps, typically 10 degrees to 20 degrees per cycle. The higher flow rates between the heat pump(s) and storage tank typically result in significant storage tank mixing.

This results in the entire volume of the tank slowly being lifted to the final desired temperature, with little to no stratification of the tank. As a result, the latter cycles result in lower coefficients of performance of the heat pump due to the elevated inlet water temperatures over the condenser coil and resulting lowered delta T.

Although multipass systems may lower overall efficiency, they are far less susceptible to performance penalties from recirculation loop temperature maintenance, such as single-pass heat pump arrangements.

In single-pass DHW heat pump arrangements, as the name implies, cold water will only make one pass over the heat pump’s condenser coil heat exchanger, where its temperature is lifted to the final desired temperature in a single step. These high-lift heat pumps typically use R-134a refrigerant or R-774 (CO2) refrigerants.

Unlike multipass heat pumps, the storage tank in single-pass equipment is intentionally not mixed. It relies on tank stratification to ensure previously heated water does not re-enter the heat pump, which would cause significant performance degradation.

As single-pass heat pump water heaters do not care about warm water inlet temperatures, their design requires a swing tank or secondary storage tank with an independent heating element (electric resistance or multipass heat pump) to accommodate temperature maintenance of return water in a central recirculation system. This combination of a primary storage tank with a high-lift heat pump and a smaller swing tank with an isolated heat source provides the highest overall efficiency for most central domestic hot water systems.

Hot Water Storage

Regardless of the type of central heat pump heating system selected, hot water storage is a critical component of all heat pump-based DHW systems. Over the last decade, engineers have been tasked with reducing storage volumes and going for higher and higher instantaneous output boilers to minimize standby losses and drive energy efficiency.

Even with standby losses included, significant volumes of hot water storage are highly beneficial when designing heat pump water heater systems.

Heat pumps are more susceptible to short-cycling compressor failures than their boiler counterparts. In addition, on a BTU-to-BTU comparison, heat pumps tend to cost more than boilers. This, combined with their larger footprint, drive the need to minimize the heat pump sizing for a project and optimize the hot water storage to meet a particular demand cycle.

This is especially true in multifamily projects with bimodal demand peaks. Sizing a heat pump to meet the peak draw in a multifamily project would be economically infeasible. However, pairing a small heat pump with a large storage volume allows the heat pump to run for extended periods during peak load and in-between peaks to recharge the storage tanks.

Increased storage volumes also provide other benefits in projects using heat pump water heaters. By relying on large storage volumes and reducing heat pump sizes, projects will reduce their connected electrical load, having less impact and cost on electrical service sizing. Reducing the peak electrical demand can reduce demand charges and provide a more grid-friendly design.

Thermal storage in domestic hot water storage can also serve the same role as an onsite battery. When paired with thermal storage, heat pump water heaters have greater flexibility to load shift either in response to time-variable energy costs or to hours where either the utility grid is cleaner or onsite renewable energy is available. The result is even more significant reductions in greenhouse gas reductions.

Centralized or Distributed

As previously mentioned, centralized heat pump-based DHW systems need special attention paid to integrating centralized recirculation systems. Not only can recirculation systems provide a challenge to centralized heat pumps, but they also result in reduced energy efficiency as the heat is lost. At the same time, water is being recirculated around a building.

One of the substantial benefits of heat pump water heaters is that they can be distributed throughout a building easily without the need to extend costly natural gas piping. In multifamily buildings, the elimination of a recirculation system not only saves energy but can also result in construction cost savings.

Distributed heat pump water heaters typically take the form of mono-block-style heat pumps with a 40-gallon to 50-gallon tank integrated with a small air-source heat pump mounted on the tank. In commercial buildings, these heat pump water heaters can be located adjacent to IT or electrical rooms. Ducting the air-inlet and outlet from the heat pump to the IT room can provide free cooling anytime the heat pump runs.

In addition, by locating distributed heat pump water heaters within an apartment unit in multifamily buildings, building owners can shift utility costs of DHW onto tenant utility meters while also providing free cooling to the apartments in climate zones where that is beneficial.

With special attention to which types of heat pumps are used in domestic hot water applications and matching heat pumps with appropriate amounts of storage, whether centralized or distributed, heat pump-based domestic hot water systems offer an opportunity to increase efficiency and significantly reduce greenhouse gas emissions.

Stet Sanborn is a principal, licensed architect and the mechanical engineering discipline leader for SmithGroup’s San Francisco office. He leads decarbonization efforts and the design of cost-effective net-zero carbon buildings, campuses and districts.

Lowell Manalo is the plumbing discipline leader of SmithGroup’s West Region. He is a member of the American Society of Plumbing Engineers and has more than 20 years of experience designing plumbing systems for various building types.