Eliminating Contaminants from Water Systems

A Q&A with LiquiTech CEO Tory Schira, a longtime champion of water security, about eliminating harmful threats to a building’s water supply.

For decades, Tory Schira has been passionate about finding ways to improve water system quality. As CEO of LiquiTech, a water safety management company, he is committed to changing how people and facilities approach water security.

Plumbing Engineer recently spoke with Schira about LiquiTech’s development of decentralized, intelligent solutions that prevent and eliminate harmful threats to water systems in buildings.

Plumbing Engineer: Tell us about your background.

Tory Schira: I used to work in finance and even then, I saw that much innovation was needed in the water safety space. Then, in 2000, my father and I found out about LiquiTech. I was immediately blown away by the company and its technology, and I’ve been here ever since.

PE: After over two decades in this industry, what have you learned?

TS: The water safety problem is multifaceted, and getting worse. There’s a widespread belief that the United States has the best drinking water in the world, but it’s simply not true — and data shows that we can do better. Many plumbing systems inherently have stagnation, warm water temperatures, and sediment accumulation, creating a perfect storm for bacterial growth.

Our drinking water infrastructure needs a critical one-trillion-dollar investment to get to the standards outlined in the Safe Drinking Water Act, which was passed in 1974. And those standards alone won’t improve the sustainability of water delivery systems, nor will they help eliminate Legionella and other waterborne pathogens.

At least a dozen people died from Legionnaire’s disease in Flint, Mich., and regular outbreaks still occur at hospitals, health-care facilities, hotels and other multistory buildings across the country. In fact, the Centers for Disease Control and Prevention estimates that 1.7 million patients contract hospital-acquired infections every year, and nearly 99,000 of those patients die.

Faulty water systems are often to blame, and many administrators try to solve the problem by adding outdated chemicals to the water supply. Unfortunately, it just damages water-bearing equipment and makes matters worse.

PE: How so?

TS: First, bacteria build resistance to chemicals over time. Second, some chemicals used to control bacteria are toxic/carcinogenic to people. Third, traditional oxidant chemicals are temperature intolerant. They’re fairly effective at killing Legionella in cold water, but not hot water, where the bacteria thrive.

And when these chemicals are in hot water, they cause a fourth problem: corrosion and damage to plumbing systems. Coupled with sediment buildup, this becomes extremely costly to repair. It’s a common situation: when you try to fix one thing, you break something else.

However, at LiquiTech, we practice a do-no-harm strategy and a smarter way of doing things. All our products and services are proven to be harmless to people and water-bearing equipment. Instead of traditional chemicals, we use copper-silver ionization, ultraviolet disinfection and filtration techniques that are safe and sustainable.

We also offer comprehensive diagnostic, management, and data services, where we proactively test, analyze, monitor, and maintain buildings’ water and plumbing systems.

PE: How do you support plumbing engineers?

TS: Plumbing engineers are the heart and soul of water safety. They understand the flaws existing in traditional designs, so we work closely with them to build better systems. And after so many years in the industry, we speak their language.

We ensure engineers working on an existing building or planning a new one have everything they need to protect the facility’s water supply from pathogens and sediment and prolong the life of its plumbing infrastructure. We are helping to build smarter, more sustainable, and safer environments.

PE: What’s your approach to enhancing water safety in existing systems?

TS: We begin with comprehensive diagnostics, working closely with customers to identify potential issues. We test for more than 10,000 different bacterial genii. We use laser particle distribution analysis to determine the amount of solids coming into a building through the water supply. We also examine the water’s chemical composition, pH and conductivity.

We do all this because customers don’t need short-term fixes that won’t address a problem’s root cause and will simply trade one issue for another. Instead, we offer long-term, sustainable improvements to provide clean water for everyone in the facility and provide usable data to inform future services.

PE: Tell me about LiquiTech’s multibarrier approach.

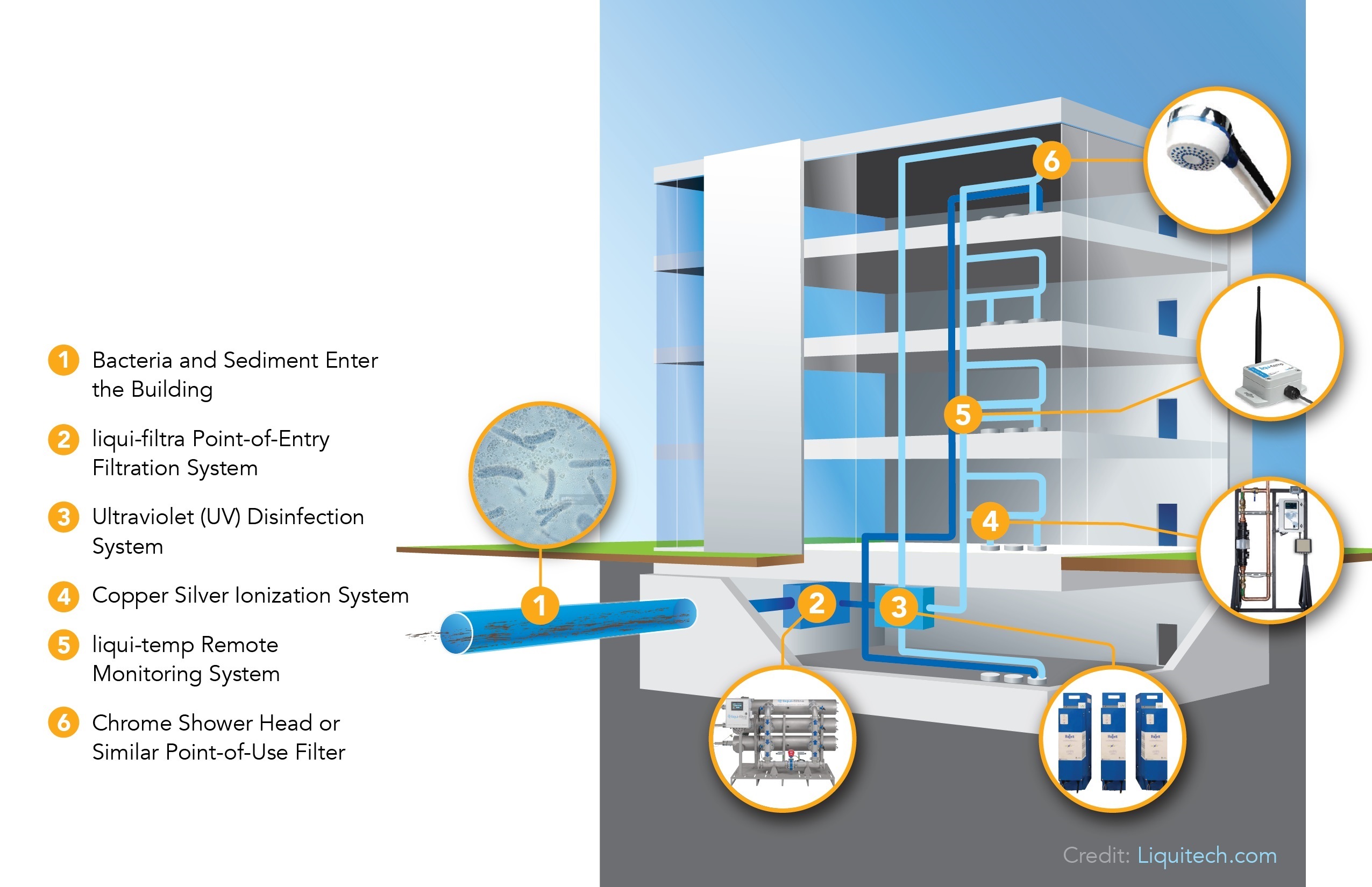

TS: The first line of defense in protecting a building’s water supply is our liqui-filtra point-of-entry filtration system. It’s an automatic, self-cleaning filter that removes sediment, which causes equipment failure and is a food source for bacteria. Stage two is ultraviolet disinfection, which is configured to prevent harmful microorganisms — including Pseudomonas, Cryptosporidium, Giardia and Mycobacteria — from invading the facility.

It’s not enough, however, as many bacterial contamination problems are systemic, with preexisting infestations throughout the plumbing infrastructure. So, the next step is copper-silver ionization, which prevents Legionella from growing or proliferating within a building’s water system.

Unlike conventional chemicals, our approach has no harmful byproducts or side effects, so it’s safe for human consumption and won’t damage plumbing. We also offer point-of-use filters for showers, sinks and ice machines to provide a final, failsafe barrier against bacteria.

PE: With a multibarrier system in place, is it still necessary to monitor and maintain water inside a building?

TS: It’s essential because water environments constantly change, and even small changes can impact safety. Four main categories must be constantly monitored, which we refer to as TTDD: time, temperature, distance and

disruption.

Time is a key factor because water quality declines when it sits stagnant in aging plumbing infrastructure for long periods.

Temperature changes affect bacterial growth in a building’s existing water and the water coming in from municipalities. These fluctuations can also lead to increased accumulation of harmful chemical disinfection byproducts, including total trihalomethanes and five haloacetic acids.

When water travels long distances, it becomes more likely it will pick up sediment and dangerous bacteria. And that distance includes how far the water travels to reach a building’s point of entry, as well as the distance it travels throughout the facility.

Then there are disruptions that impact water quality. Some disruptions are obvious, such as water main breaks, building occupancy changes, construction projects and severe storms. However, even smaller disruptions can have an effect, such as relocating a sink, capping off a dead leg, mixing valve adjustments and changes in water pressure.

It’s easy for these disruptions to go unnoticed, which is why we’re constantly monitoring everything that happens to a building’s water in real time. I like to say that LiquiTech is at the forefront of providing an extensive water security architecture to our customers.

PE: It sounds analogous to a cybersecurity system.

TS: Exactly. A company might have firewalls and antivirus software in place to protect their data, but they also need security analytics and a system that will proactively scan for breaches.

We’re also on the hunt for anomalies, but instead of computer viruses, we protect buildings from pathogen attacks.

And we don’t simply alert you to an issue — we perform corrective actions instantly. For larger issues that can’t be solved remotely, we dispatch engineers or technicians who will work closely with our customers to address the problem.

PE: Tell me about your team.

TS: We employ passionate people who are committed to our mission, vision and values. Our team has mechanical and chemical engineers, manufacturers, technicians, industry experts and customer success professionals. Their work is critical because our customers help us innovate.

PE: Where can people learn more about LiquiTech?

TS: Well, the first place I’d suggest is www.liquitech.com. From there, you can contact us directly. We’re on Twitter, YouTube and LinkedIn. You can visit our headquarters in Lombard, Ill., or make an appointment to tour one of our customers’ facilities. We also would be happy to hold a Lunch and Learn session at your office or a local ASPE chapter.

And we’ll be hosting a webinar with Plumbing Engineer in October; be sure to check out the recording if you can’t attend live.