Raising the Bar for Safer DHW System Design and Distribution

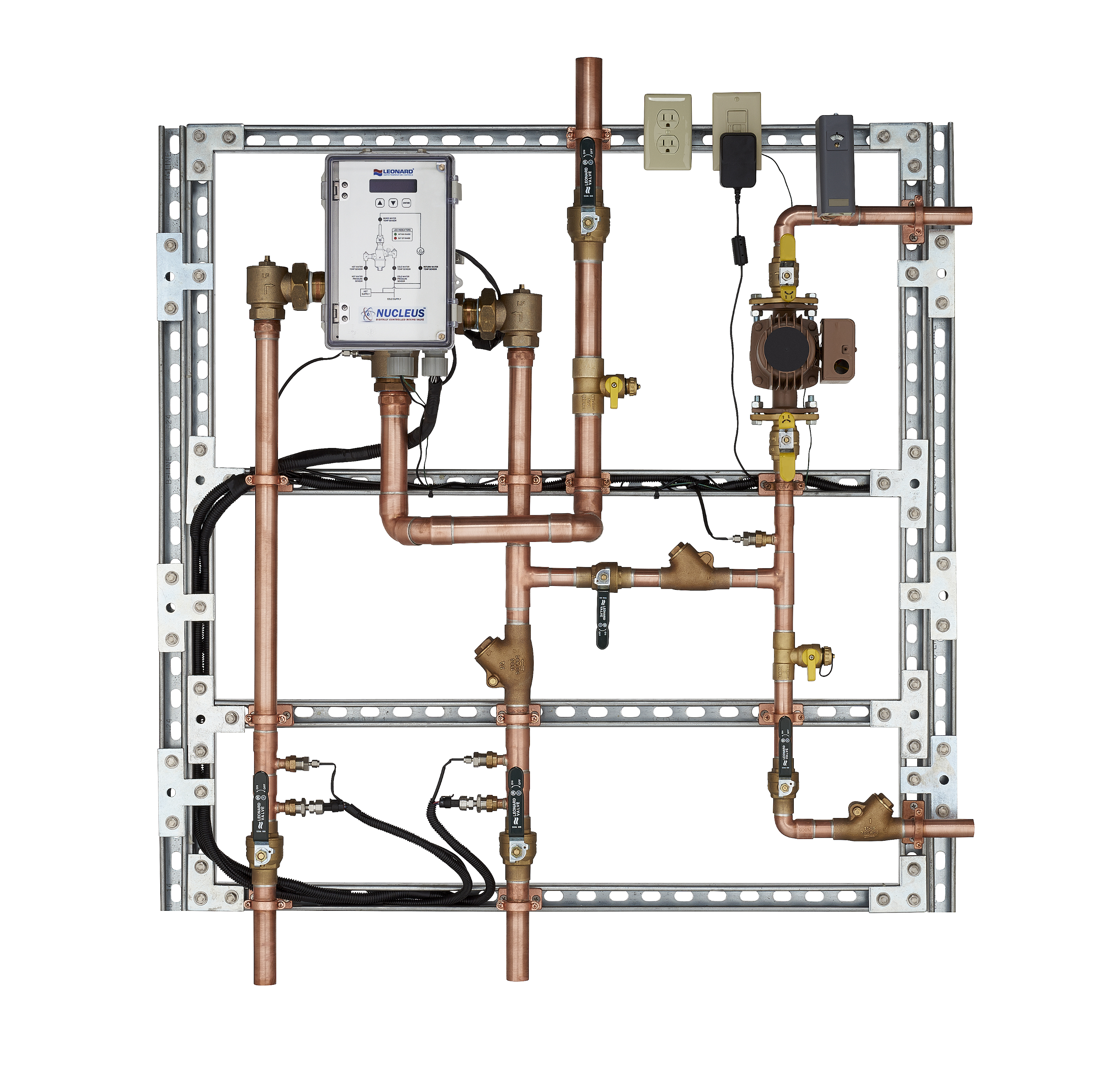

Feature-packed DMVs provide the vehicle for an ultra-safe and efficient domestic hot water system design.

A revolution is happening in today’s commercial plumbing marketplace, specifically when it involves domestic hot water system designs. Manufacturers now supply better-performing digital mixing valves stacked with features and enhancements that carry the capabilities of remote temperature adjustment, high-temperature sanitization, building management system integration, multiple temperature and pressure measurement points, flow measurement, self-cleaning, self-monitoring and self-balancing.

These features and the parallel capabilities and advances in digital smart circulator pumps for these applications, allow building designers and specifying engineers to think about the domestic hot water system in ways never previously imagined. In the past, conventional mixing valve technologies such as bellows, wax or bi-metal would simply allow the end-user to set the temperature at initial flow condition. Active monitoring of upstream (inlet) or downstream (outlet) temperatures or pressures was not an option.

The balancing of the recirculation system was accomplished by an iterative process of manually throttling a return ball valve or circuit balancing valve on the return line, based on a fixed temperature loss in the system.

Typically, it would take multiple iterations over days to stabilize system temperatures under pure circulation. If system conditions experienced even slight variations in temperatures or pressures, facility managers were faced with reactionary tactics in the face of no active feedback loops or data that could be served up from the device.

Today, due to the stacked features within DMV offerings, there is an active shift from reactive to proactive management of the domestic hot water system. This is now allowing facility managers a complete thought process transformation. Previously, the master mixing valve was thought of as a high-maintenance device — “the enemy.” Now, the thinking is that DMVs combined with energy-efficient smart pumps can “change the game.”

Simply put, feature-packed DMVs provide the vehicle for an ultra-safe and efficient domestic hot water system design.

Several frameworks are available to operate when choosing the applicable path to domestic hot water system design, depending on the specific application. This discussion is not, by any means, comprehensive but rather hopes to illustrate how today’s DMVs can help a system designer or specifying engineer achieve mutual outcomes of enhanced domestic hot water safety while satisfying an established standards directive

VHA Directive 1061

The Department of Veterans Affairs issued a Transmittal Sheet (Feb. 16, 2021) with updates to the Veterans Health Administration directive addressing the prevention of health-care-associated Legionella infection and scald injury from water systems in VHA buildings. Specifically, these buildings were those where patients, residents or visitors stayed overnight; where employees are required to sleep overnight; and for the management of select outdoor nonpotable water systems.

Engineering control strategies exist for the ongoing prevention of Legionella growth within those situations, the deadly bacteria responsible for Legionnaire’s Disease. Specifically, for incoming potable water, the pressure and temperature must be monitored in addition to measurement at water storage tanks, discharge from hot water source equipment, water at the return of circulation loops and water supplied to representative areas of the building (i.e., risers).

The directive also stipulates the data must be reviewed, at a minimum, weekly.

Q: If the digital mixing valve monitors temperatures and pressures at the mixing valve inlets, how could one also measure incoming potable water temperature and pressure and measure all the additional points previously stipulated?

A: With a DMV such as the Leonard Nucleus, the primary valve offering allows four temperature measurement points and two pressure measurement points. With the addition of a simple plug-in expansion card, one can now measure another four temperature points and one pressure measurement point.

These points can be served up to a building management system directly with the onboard BACnet Testing Laboratories-approved protocol card with six standard industry-recognized protocols. They can be viewed in real-time at any time with user-input alarm highs and lows. This allows for easy, real-time access to key facility data points that hinge on compliance and pivot the safety manager’s perspective to risk-averse from previously available technologies.

ANSI/ASHRAE Standard 188-2015: Legionellosis Risk Management for Building Water Systems

Legionella, a gram-negative bacteria, causes pneumonia-like Legionnaires’ Disease. It also can cause a less severe influenza-type illness known as Pontiac Fever. The Centers for Disease Control and Prevention estimates that more than 10 percent of the documented 8,000 to 18,000 Legionnaires’ cases in the United States are fatal. Most cases are the result of exposure to Legionella bacteria associated with building water systems.

ANSI/ASHRAE Standard 188-2015 applies to human-occupied commercial, institutional, multiunit residential and industrial buildings. It is intended for those involved in the design, construction, installation, commissioning, operation, maintenance and service of centralized building water systems and components.

At the heart of minimizing the risk associated with Legionella, this program works to establish a water management program inclusive of a Program Team, describe the water systems in the building, evaluate hazards or analysis, create control measures and explain how they are applied, monitor corrective actions, confirm that the program is being implemented, and establish relevant documentation.

As one reads through the entire written standard, two common themes are prevalent: monitoring of water temperatures and disinfection at multiple levels.

Q: Can I monitor and disinfect with a digital mixing valve to achieve compliance with Standard 188?

A: Yes, the majority of DMVs being offered today allow some degree of monitoring as well as a hot water sanitization feature, which provides for disinfection by high-temperature hot water. One such device, the Leonard Nucleus, has capabilities for up to eight temperature measurement points, three pressure measurement points, and two points of flow measurement rates within the domestic hot water system.

All these points, along with several others, can be served up to the building management system and monitored in real time. Also, each can have user-input high- and low-level alarms to trigger alarm conditions that instantly notify appropriate personnel if something is out of specification or tolerance.

The ability to disinfect the entire DHW system with water at a minimum of 158 F (assuming available) also comes standard on the Leonard Nucleus systems. The programming is key-code-protected and involves multiple decision-making levels in the logic before allowing safe engagement in the process. It is programmable for up to 12 hours of sanitization and can be done locally at the keypad or remotely through the BMS.

Previously not possible with conventional mixing valves, DMVs continue to inject a safer value proposition to key facility managers and decision-makers and re-invent DHW systems.

Scalding, Thermal Shock Issues

DMVs are the single most important safety device in a properly designed DHW system. They are intended to lower the outlet temperature being fed from the hot water source to a safe, useable level — that which prevents burns, thermal shock or scalding of downstream device end-users.

Hot water at 140 F causes a first-degree burn in just 2 seconds; second- and third-degree burns can happen in 5 seconds. This simple fact cannot be ignored in applications where bathers and end-users are either young children or older adults who may not be able to remove themselves from the water stream.

It is a delicate balance when trying to solve the Legionella issue and the risk of thermal shock in a DHW system. The solution that makes most sense addresses both issues head-on. Ideally, one would store hot water at a minimum of 140 F, which kills the potentially deadly Legionella bacteria within 32 minutes, and then install a DMV downstream of the hot water source. It would then allow temperatures to be reduced to safe levels below 120 F.

There are two keys to a properly designed system. The first is to minimize water flow stagnation in the system by designing a proper circulating loop. The second is to bring a portion of the DHW back to the heat source, so there is always some “sanitization effect,” where the bacteria can be killed at the 140 F or more source temperature.

Today’s energy-efficient smart pumps, such as Taco Comfort Solutions’ 0034e, provide the designer or specifying engineer many options to achieve better-performing, safer recirculation systems. They, too, are stacked with features: five operating modes, including constant pressure; fixed speed; Taco’s exclusive self-adjusting proportional pressure; and 0V to 10V capabilities.

As the world is evolving, so too are master mixing valves to help alleviate design concerns regarding these issues. Digital master mixing valves are now filled with design features such as cloud-based logging and monitoring of all critical system data, with the ability to send alerts for any temperatures that may fall out of range. This allows for quick response and resolution of issues.

These valves now have programming capabilities to create safe disinfection cycles and kill the bacteria throughout the DHW system. They are the perfect vehicle to solve the deadly Legionella issue while simultaneously protecting end-users from burns, scalds and thermal shock. Add in the supplied features of self-cleaning, self-monitoring and self-balancing, and maintenance and installation of these devices is a breeze.

Simply put, DMVs packed with features are our future and are a significant element to ultra-safe hot water system design and distribution.