PEX 101

Recommendations on how to make your PEX installations simpler.

Use of PEX (cross-linked polyethylene) has become very widespread among contractors in the plumbing industry, largely due to its ease of use. Whether the contractor is dealing with new construction or renovations, PEX piping makes the project simpler, saving time and labor expenses.

Provide enough clearance for expansion and contraction

When installing PEX, remember that it expands and contracts in response to temperature; for every 10 F of temperature change, the length of PEX changes by 1 inch/100 feet of piping. Consequently, ensure you adhere to the following:

- Allow 1/8-inch of slack for each foot of PEX.

- For longer PEX runs, add loops to provide further slack. Leave enough space for these loops to contract and expand without being pressed against structural elements such as joists and wood studs.

Make sure that PEX is adequately supported

Horizontal runs of PEX must be supported every 32 inches if hanging, or every 72 inches if installed above beams. For vertical runs, PEX must be supported at least once per floor, and also keep in mind that joints add weight and require dedicated support as well. With respect to accessories, consider the following recommendations:

- Ensure that hangers are properly sized, or they can crimp and damage PEX.

- Plastic (rather than metal) hangers and straps are preferred to reduce weight.

- Protect PEX when routing through studs.

When PEX must cross wooden joists or studs, make sure the hole is drilled through the center. Then, install nail protector plates at the crossing points to prevent accidental puncturing.

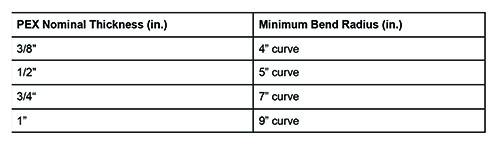

Respect the minimum bend radius

When PEX runs must be routed through 90-degree corners using elbow supports, consider the minimum bend radius allowed:

Cut PEX runs slightly longer than needed. As previously stated, PEX requires slack to expand and contract. Cutting PEX runs slightly longer than necessary, and trimming them is better than having them fit exactly, even if some waste is generated in the process. It is also important to leave a loop where the pipe ends, providing further clearance for expansion and contraction.

No matter how skilled you are with PEX installations, you will require high-quality tools to handle this material correctly. These tools are not expensive, and you can get a complete toolkit for less than $200. The following are particularly important when working with PEX:

- Tubing Cutter — A squared-ended and burr-free cut ensures that PEX is connected properly. To achieve this result consistently, use a high-quality tool.

- Crimp Tool — Fundamental for fastening crimps correctly to PEX fittings.

- Tubing Expander — May be required in some connections where the crimp tool is not suitable.

- Go/No Go Gauge — Required to assess the quality of connections, with both crimp tools and tubing expanders.

- Clamp Removal Tool — Needed to remove poorly-installed crimps.

Follow the correct procedure for PEX connections.

If you are working with push-to-connect fittings and your cuts are square and clean, you should have no trouble with the installation — all you need is a good PEX tube cutter. Make sure that the pipe is seated correctly into the fitting. Push-to-connect PEX fittings tend to be expensive, so they are only recommended when very few connections are needed.

Crimp rings involve more labor than push-to-connect fittings, but are a more cost-effective option when multiple PEX connections are required. Like with push-in fittings, a square and clean cut is very important, and then the procedure is as follows:

- Slide a crimp ring over the PEX tube ending that will be connected.

- Insert the fitting, ensuring there is full contact between the PEX edge and the fitting’s shoulder.

- Slide a crimp ring over the fitting’s connector, at a distance of 1/8 to 1/4 inch from the PEX tube edge.

- Fasten the connection with the crimp tool, ensuring that pressure is exerted around the crimp ring.

- Use the Go/No Go Gauge the crimp has been installed correctly.

Remember, there are cases where PEX is not suitable. Although PEX is extremely versatile, there are specific cases where it is not recommended. Avoid the following five applications, where PEX is unable to tolerate the long-term operating conditions:

- Downstream from a point-of-use water heater

- Within 6 inches horizontally and 12 inches vertically from recessed lights, flue gas exhausts and heating devices

- Swimming pools

- Close to petroleum-based products

- Exposed to direct sunlight

Don Rackler is the founder of Jon Wayne Service Company, a leading San Antonio plumber. Jon Wayne is additionally the largest heating and air conditioning company in the San Antonio area. Don started Jon Wayne in 2001. Recent awards for the company include Bryant Dealer of the Year and ACHR News’ Best Contractor To Work For in the South.