Wastewater Heat Pumps: Efficiency Regardless of Climate

Part 3 of this series discusses how sanitary waste energy exchange systems (wastewater heat pumps) can increase DHW efficiency and reduce carbon emissions.

Cities and states nationwide have recently accelerated new policies to decarbonize buildings and move more building energy end-uses to all-electric systems. Domestic hot water systems offer an ideal opportunity to increase efficiency, reduce carbon emissions and offer significant utility cost savings to owners considering heat-pump-based conversions.

Air-source heat pumps can operate efficiently at low-ambient temperatures while saving on utility costs compared to natural gas boilers. However, colder climates can present a significant challenge in matching these heat pumps for domestic hot water use. Sanitary waste energy exchange (SWEE) systems offer an opportunity to provide these benefits even in cold climates.

Sanitary Waste Energy Exchange

SWEE systems use heat pumps to extract heat from sanitary waste leaving buildings to heat incoming cold water for domestic hot water usage. As was covered in the first article of this heat pump water heating series (https://bit.ly/3IBAhKA), the higher the source temperature, the higher the efficiency of the heat pump. In buildings, up to half of the water used is heated for handwashing, showers or laundry; once that warm water is discharged into the sanitary system, it becomes an excellent source for heat pumps.

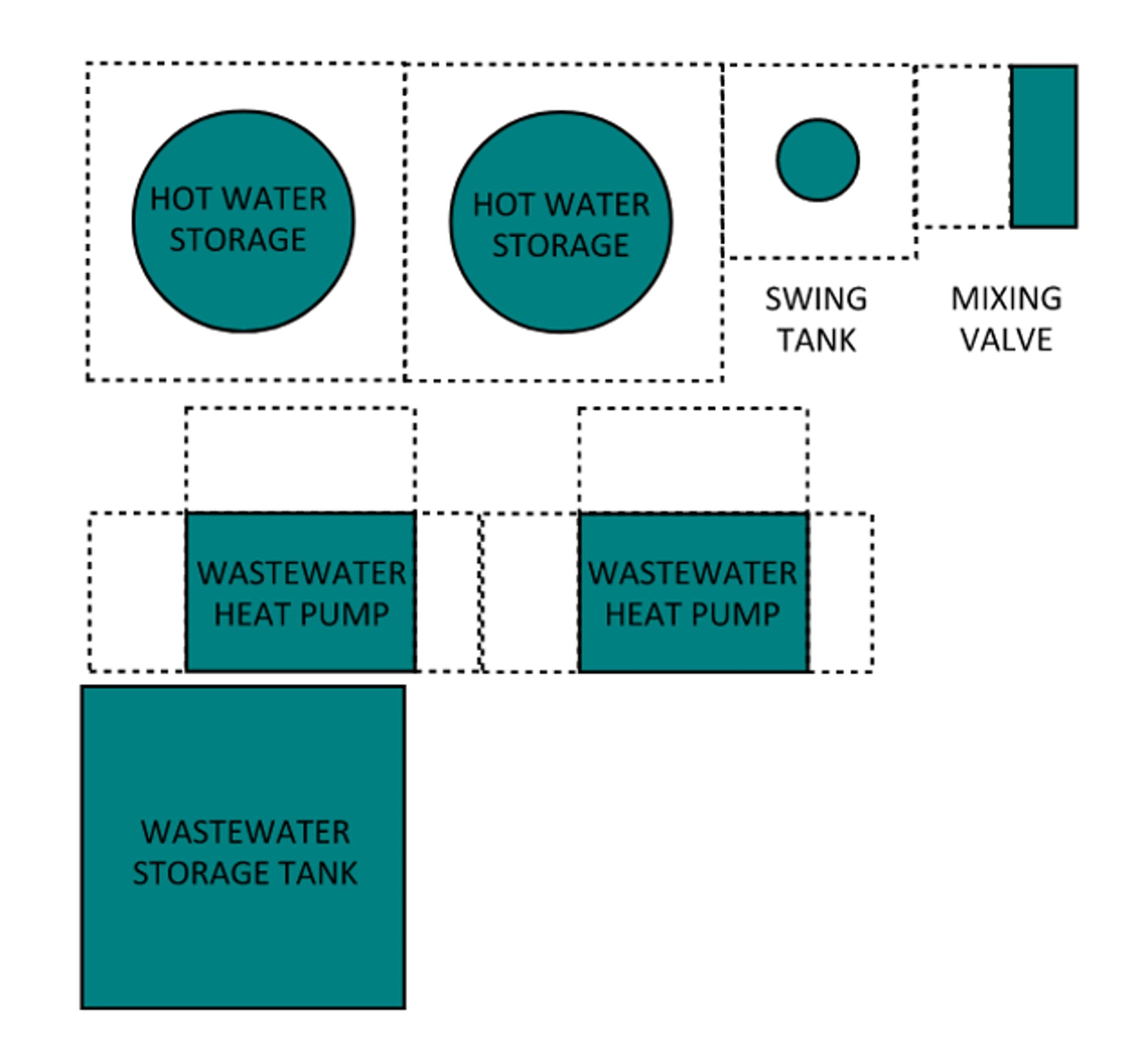

A wastewater heat pump is a form of a water-source heat pump and uses a refrigerant circuit to transfer heat from the sanitary waste to the incoming cold water. The wastewater heat pump system is made up of a sanitary wastewater storage tank collecting the wastewater from the building and a pump transferring the wastewater from the tank to the heat pump (see Figure 1).

The heat pump cools the wastewater and shifts the heat to domestic cold water for use as hot water at fixtures and appliances within the building. The cool sanitary wastewater is pumped back to the storage tank and then discharged to the municipal sewer.

Boiler, Air-Source Heat Pump and SWEE Heat Pump Design Considerations

When designing heat pump systems, whether air-source or wastewater heat pumps, it is important to account for the larger space requirements compared to natural gas or electric boilers. For a similar heating output, the footprint of the heat pump itself can be up to 10 times as large as typical condensing boilers. Still, air-source heat pumps include large auxiliary air coils requiring full-length access for maintenance (see Figure 2).

As mentioned in the second article of the heat pump water heating series (https://bit.ly/3IBAhKA), heat pumps work most efficiently when paired with large storage volumes. So, in addition to the larger footprint of the heating equipment itself, heat pump systems require extra space for storage tanks.

While typical boiler systems are sized for much of the heat recovery from the boilers with minimal storage capacity, ranging in the 100- to 200-gallon range, air-source and wastewater heat pump systems can have hot water storage up to the thousands of gallons.

Unlike typical boilers, heat pumps work best when they can run consistently for long periods rather than cycling on and off. The optimal sizing approach to heat pump systems is to select the heat pumps and storage so that the load on the heat pumps is as constant as possible during peak and off-peak hot water demand periods.

During peak periods of hot water demand, the heat pumps and charged storage tanks supply hot water; conversely, during off-peak periods, the heat pumps supply the reduced hot water demand while also refilling the storage tanks for the next peak period.

Compared to air-source heat pumps, wastewater heat pumps have the benefit of allowing for smaller heat pump footprints and more flexibility with being installed indoors. SWEE systems do have another storage tank, which is required to collect and store the warm sanitary waste for when there is a demand for hot water (see Figure 3).

For a 90-unit dwelling project, the recommended wastewater storage tank is 8,000 gallons but can depend on how variable the flow rates are anticipated to be and how much hot water storage is available. Although there is the additional wastewater storage tank, these tanks are typically below grade and, therefore, still have an overall smaller footprint when compared to air-source systems.

Performance Comparison

The transition to heat pump systems presents the opportunity to generate domestic hot water at improved efficiencies. Gas boilers operate at efficiencies between 0.85 to 0.9, with condensing boilers running at up to 0.97. Heat pump coefficients of performance (COP) are typically in the range of 2.5 to 4, but as noted earlier, optimal outside air temperatures for air-source, or condenser water or ground-loop temperatures for water-source, can be as high as 5.

Further, wastewater heat pumps can benefit even more greatly from the high temperatures seen in sanitary wastewater. COPs for heat pumps can be even higher when supply temperatures can be lowered, in heating applications, to be closer to the source temperature.

All-electric heat pumps, of course, present a significant contribution to the mission of decarbonizing buildings. Air-source and wastewater heat pumps can provide heating with significantly fewer carbon emissions than their natural gas boiler predecessors.

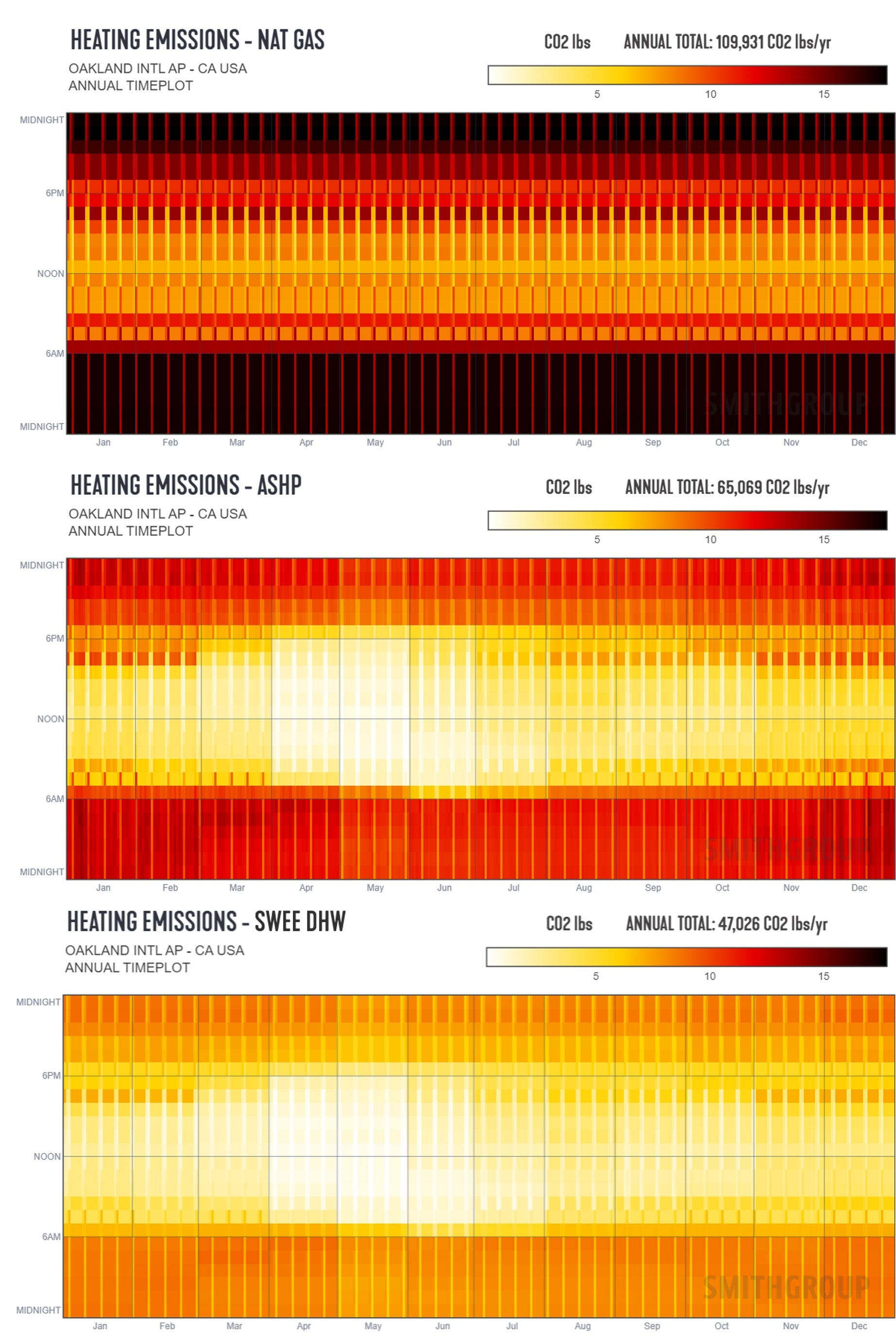

For the same 90-unit residential project referenced previously, the domestic hot water load profile was modeled and used to calculate the carbon dioxide emissions for a boiler system, air-source heat pump and SWEE domestic hot water system (see Figure 4).

Considering gas-fired boilers as the baseline, an air-source heat pump can reduce carbon emissions by approximately 40%. Further, a SWEE system can reduce close to another 30% for a total reduction of slightly more than 57% from the baseline. It does so with the smallest nominal capacity equipment as compared to boilers and air-source heat pumps.

Although SWEE systems have not yet seen the rapid rise in installations that air-source heat pump systems have, they offer significant benefits when compared to their air-source heat pump and natural gas-based counterparts. Regardless of climate zone, sanitary waste energy exchange-based heat pumps offer a significant efficiency boost and carbon emissions reduction for domestic hot water applications.

With the alignment of high thermal quality effluent flow and domestic hot water demand, these systems can also minimize footprints compared to their air-source heat pump counterparts. In challenging climate zones or tight sites with limited roof or site areas, SWEE systems offer the highest performance option for projects striving for deep carbon savings.

SWEE systems should be considered a front-runner option for any new domestic hot water system, especially for high-demand scenarios such as multifamily housing, dormitories, student housing and athletic facilities.

Stet Sanborn is a principal, licensed architect and the mechanical engineering discipline leader for SmithGroup’s San Francisco office. He leads decarbonization efforts and the design of cost-effective net-zero carbon buildings, campuses and districts.

Jennifer Ma is a mechanical engineer at SmithGroup specializing in the plumbing discipline. She has 10-plus years of experience designing systems with an emphasis on energy and water efficiency.